DGD-220B Automatic Horizontal Pre-made Pouch Packing Machine(50g up to300g)

Introduction

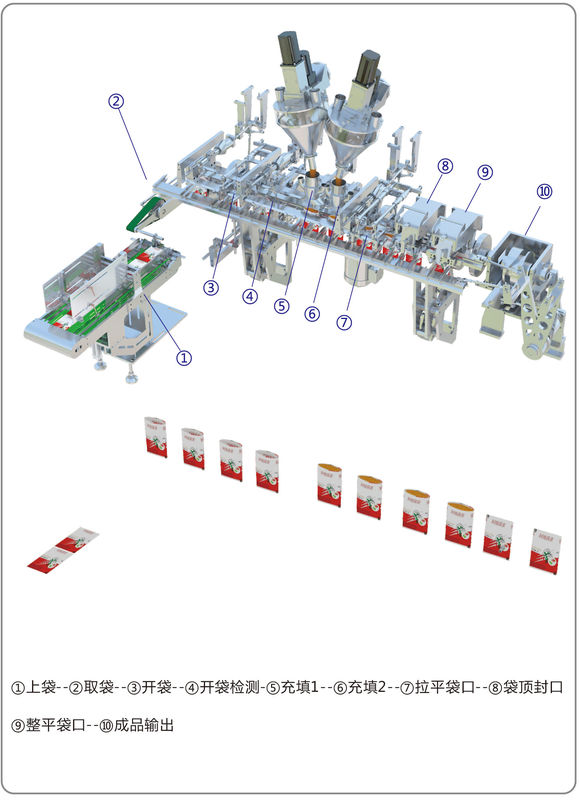

DGD-220B Automatic Horizontal Bag Packaging Machine contains pouch taking unit, pouch open unit, inflatable institutions, filling, heat sealing, cold sealing shaping and other institutions. Done by importing high-precision cam splitter that coordinating the operation of each mechanism, the encoder on the cam will feedback signal. Under PLC control, it will achieve that taking bags → opening bags→ filling → sealing → detection finished products. Machine design is reasonable; new appearance, large curved plexiglass door, safety and environmental protection in line with production requirements. At the same time by replacing the filler can automatically fill powders, granules, liquids and other materials on this machine. Applicable to all types of pre-made bags.

Advanced Features

1. This equipment is mainly used in the production of various types of prefabricated bags. The packaging is well formed and beautiful, and there is almost no waste of packaging materials and materials.

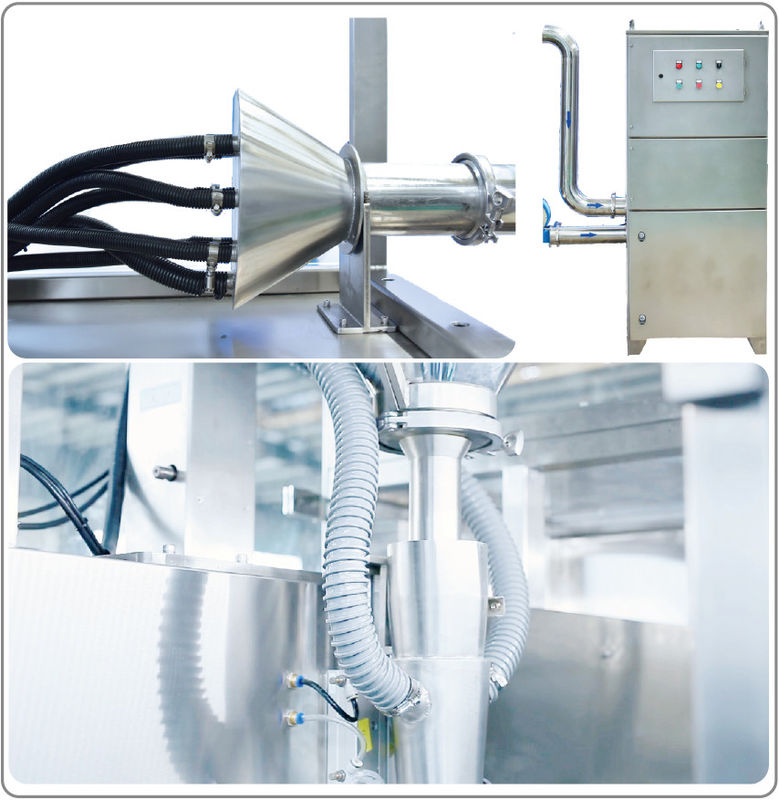

2.Environmental Protection: The whole machine is closed design, which isolates the dust inside the machine and is equipped with a stainless steel dust removal pipe system, which is environmentally friendly and pollution-free. (Dust removal pipes and dust collectors are optional).

3. Easy to maintenance: Upside-down ironing block structure, convenient for maintenance and cleaning

4. Save cost, with bag opening detection function: If the bag is not opened or the bag is incomplete-opening, no material charging and no heat sealing. No waste, and the production cost is saved for the user.

5. More stable: change the single folder to double folder function, the bag delivery process is more stable.

6. Using Spanish cam technology, instead of the internal cam, circle movement running more accuracy and ensure no out of scope.

7. The bag taking structure is optimized to prolong the bag suction time and take the bag more accurately. At the same time, the large-capacity bag placement mechanism can store about 600 bags at most. When the equipment is running, the bag placement frequency is reduced and the production efficiency is improved.

8. More durable: Exquisite design technology and imported CNC parts processing, high precision and high standards, ensure the stability and durability of each part.

9. Temperature control integrated module: Real-time monitoring of temperature changes, the operation is clear at a glance. Thereby effectively controlling the heat sealing mechanism and ensuring the reliability of the sealing makes the packaged product easy to use.

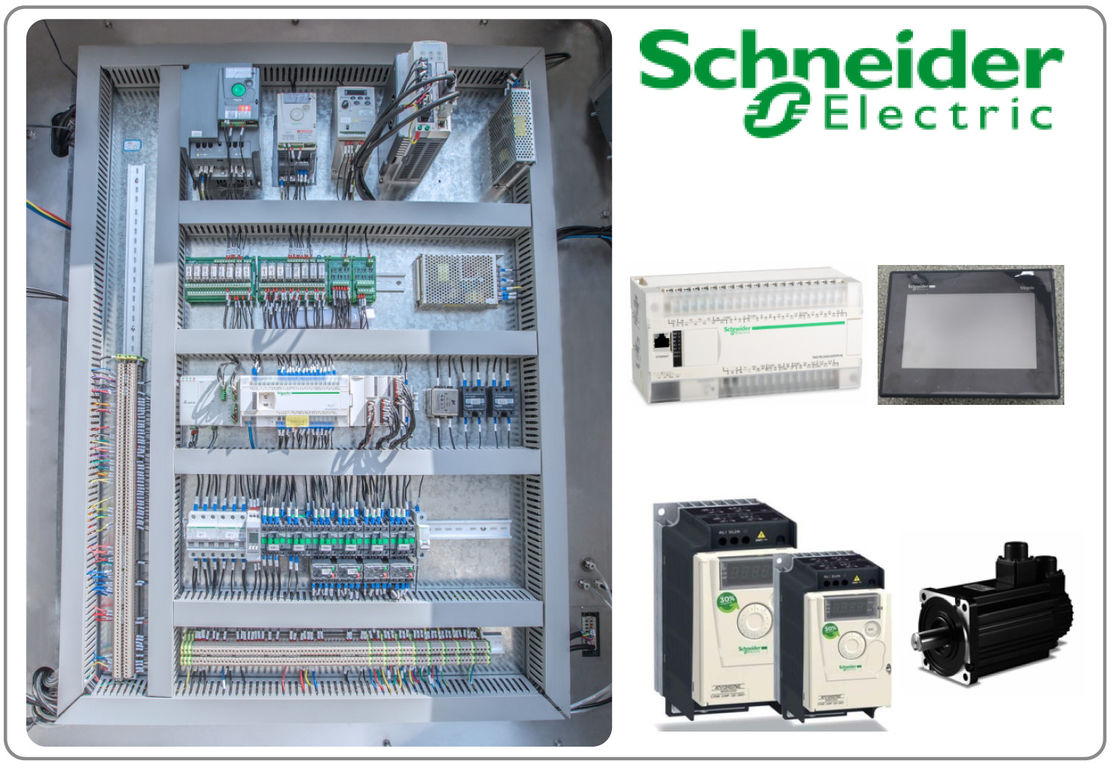

10.The main configuration of the whole machine is Schneider Electric System (PLC programmable controller, man-machine interface, servo system, inverter, switching power supply, etc.). Safer, more reliable, more efficient and more environmentally friendly, it will bring you more economical energy loss).

12. Multiple safety protections (Japan SMC vacuum generator, air source processor with air pressure detection, etc.), to maximize the stability and reliability of the equipment operation.

13.Comes with a small compressed air storage tank to reduce the impact of outside air pressure fluctuations on bag loading and bag opening. At the same time, the air source pressure detection system is standard.

Equipment Allocations

| S.N |

Name |

Brand |

| 1 |

CPU |

Schneider |

| 2 |

Touch Screen |

Schneider |

| 3 |

Frequency Converter |

Schneider |

| 4 |

Servo System |

Schneider |

| 5 |

Proximity Sensor |

Sick |

| 6 |

Power Switch |

Schneider |

| 7 |

Vacuum Generator |

SMC |

| 8 |

Fan |

SUNON |

| 9 |

Encoder |

OMRON |

| 10 |

Circuit Breaker |

Schneider |

| 11 |

Button |

Schneider |

| 12 |

Pressure Switch |

SMC |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!