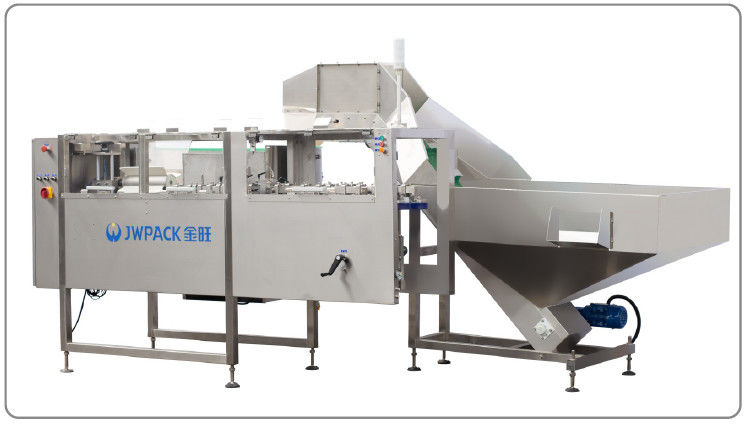

LP-200B Automatic Bottle Unscrambler

Introduction

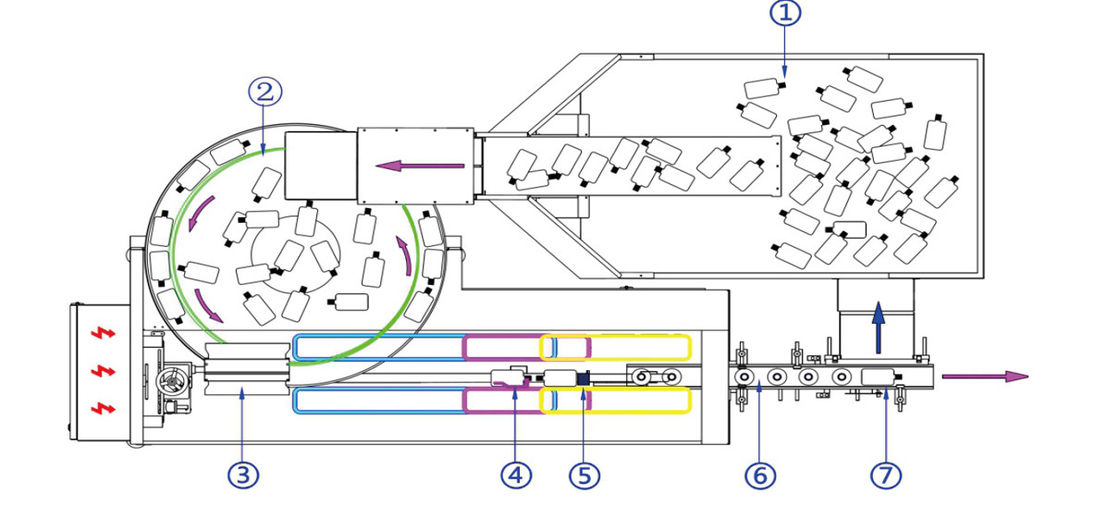

LP-200B Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability. It can reduce the labor force. For now it has been widely used in agrochemical industry - BASF, Syngenta, Suzhou FMC, Rotam and other well-known agricultural enterprises have been used for many years.

Features

1. Compact structures, with three buttons to operate the machine. 50ml-1000ml bottles are applicable.

2. When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml.

3.The whole machine is covered with organic glass, you can open all the cover for easy adjustment

4.All the organic glass cover is installed with the sensor. The machine only can start when all the organic glass cover are closed, and will stop when any of the door is open.

5.Automatic bottle elevating function, you only need to put the bottles in the bottle elevator, a sensor is installed in the rotary plate, it will automatically elevates the bottles when there is not enough bottle, it will start when the bottles are enough consequently.

6.Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

7.Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

| NO. |

NAME |

Brand |

| 1 |

Frequency converter |

DELTA |

| 2 |

Magnetic switch |

Schneider |

| 3 |

Count Photo electricity |

Sick |

| 4 |

Switching power supply |

Schneider |

| 5 |

Solenoid Valve |

Ftec |

| 6 |

Circuit Breaker |

Schneider |

| 7 |

Magnetic Switch

(Safety Door Switch)

|

Schneider |

| 8 |

Intermediate Relay |

Schneider |

| 9 |

Button |

Schneider |

| 10 |

Exhaust Fan |

Sunon |

| 11 |

Turbo Reducer |

Ucan |

| 12 |

Motor |

Ucan |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!