100g powder,60pouches/min Pouch Packaging Machine

1. Introduction:

DXD-130D Automatic Horizontal Pouch Packing Machine contains motor film-releasing, film forming, bottom sealing, vertical sealing, cutting, filling, pouch transferring and top sealing. The cams on the main shaft finish the coordinated action driven by the motor and the encoder on the main shaft feedback the position single. Under the control of the PLC, it realizes the function of film roll→film forming→film in-shape→powder filling→sealing→ finished products transferring. At last, the finished products enter the counting device, and then manually put them in boxes or cartons. The machine designs properly with a beautiful appearance. It adapts standard stripe sealing. It can realize automatic power, granule, SC, EC, AS filling with changing the filling device. The organic glass cover can prevent the flowing of dust which is more environmental-friendly.

2. Features:

High efficiency, Safe, Environmental Friendly

2.1 Easier and high efficiency operating system

It is with compact intellectual system which makes the operation easier. One key adjusting

① Temperature control module, it monitors the temperature changes and visible operation

②Servo film releasing system, volume adjusting can be done by pressing only 1 key.2. Overall structure which is more suitable to the agrochemical production

2.2 Safe working environment

① the machine uses France Schneider Electrical System (PLC, HMI, Servo System, Inverter, Power Switch, etc) with the features of safe, reliable and high efficiency.

② Multiple Safety Protection (Japan SMC Vacuum Generator, Air treatment with air pressure inspection, power supply protector, color detector, film releasing limit protecting device, etc ) these protecting devices will make sure the normal operation of the machine.

2.3 Overall structure which is more suitable to the agrochemical production

① JW has been serving the agrochemical industry for more than 10 years, relying on the experiences, the machine is making with SUS304, it is with the features of anti corrosive. The organic glass cover can prevent the dust from going outside. This is environmental friendly and no pollution.

② All the connecting rods are using SUS304 which is firm and not getting out of shaped, other suppliers use welding connecting rods which are easy to break.

③Applicability of Filling Devices

The machine reserves the connector for powder, liquid, viscosity and granule products. Also it has reserve in the software; the operator only needs to plug the correct plug will realize different products filling. The function can be used in the touch screen.

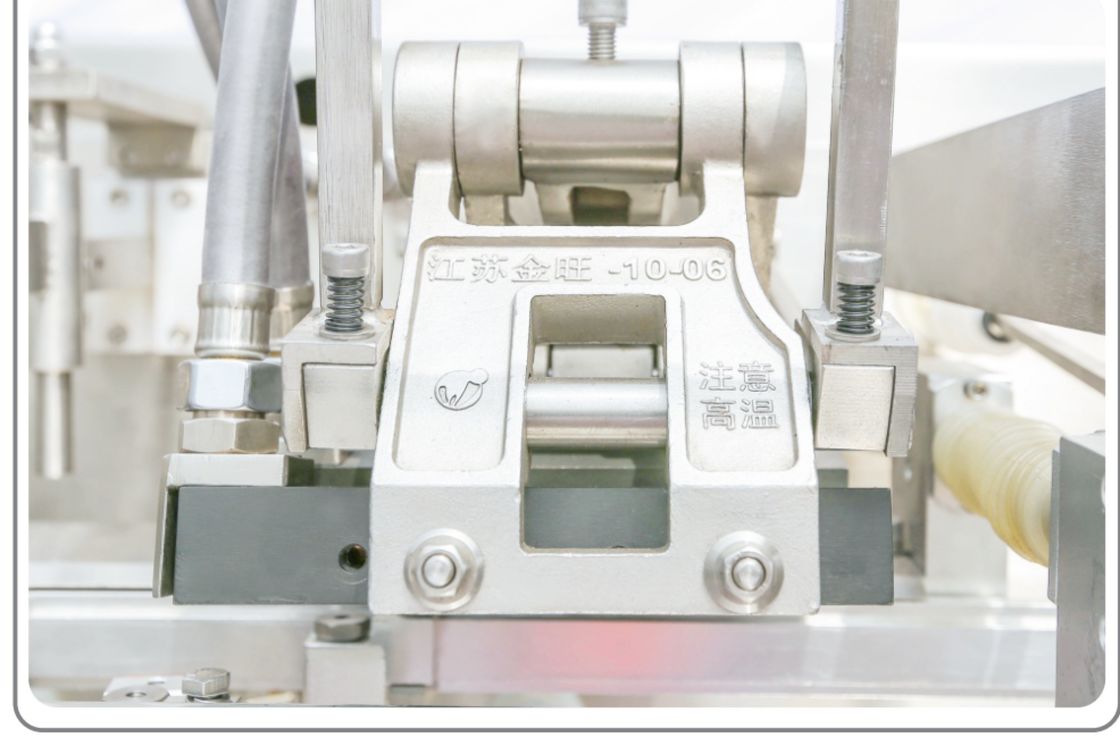

④Special Coating

In order to prevent the heating block will have sticky problem, we do special coating on the bottom, vertical and top sealing blocks.

⑤Film Connecting Device

When a film roller is finished, you do not need to pull out the rest film roll, only need to connect the new roll with the finished one and then start the machine, this will reduce the wastage of the packing material, it is an optional function.

2.4 Producing good looking products

①Diamond Tear, the cylinder drives the cutting do repeatable work to have the tear, Also there is tear collecting device, this is an optional function.

3. Main Technical Parameter

| 1 |

Capacity |

60 pouches/minute |

| 2 |

Applicable Pouch Size |

W: 70-130mm, H: 80-180mm |

| 3 |

Packing Volume |

200ml |

| 4 |

Filling Precision |

±1% |

| 5 |

Film Roll Inner Diameter |

Φ70-80mm |

| 6 |

Film Roll External Diameter: |

Φ500mm |

| 7 |

Power Source |

Three Phase, AC380V, 50HZ |

| 8 |

Power |

4.5KW |

| 9 |

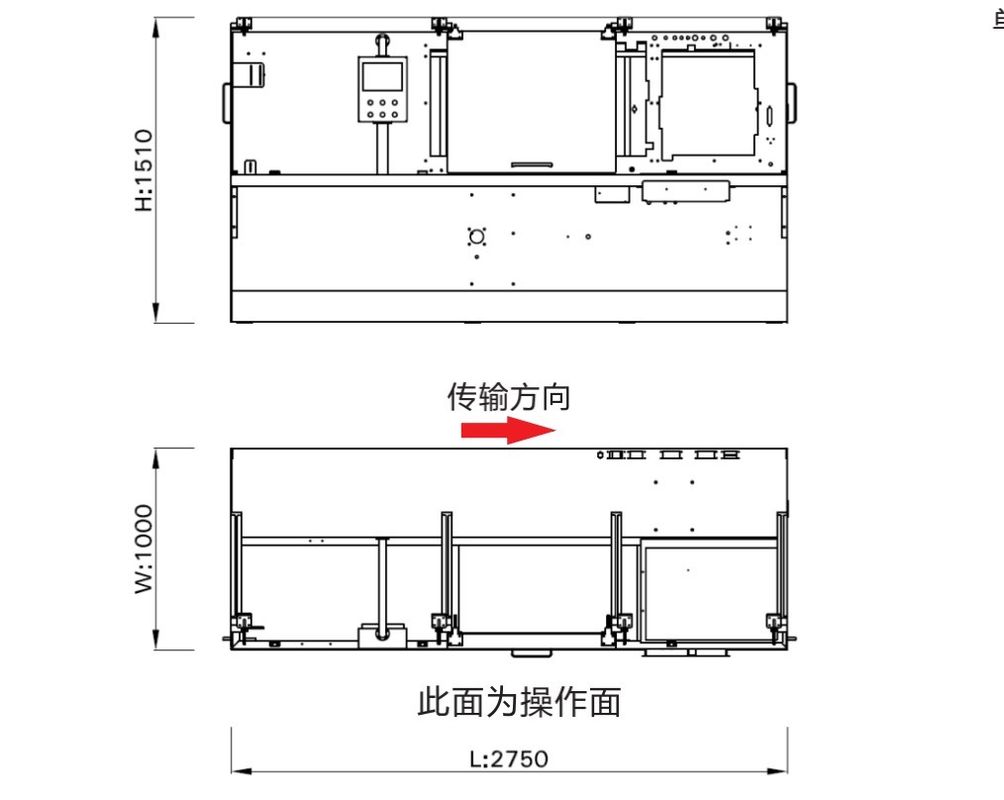

External Dimension: |

2580×945×1550mm (L*W*H) |

| 10 |

Weight |

1350KG |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!