High Speed Automatic Capping Machine(100ml-1L) 6/8 Capping Heads Pick and Place type

Pick and place type Rotary Capping Machine is used for closing plastics screw caps, especially for the caps with lock ring. It is widely used in industries like foodstuff, pharmacy, daily chemical, cosmetic, fertilizer, etc.

Automatic rotary cappers are designed to handle a wide range of caps including screw caps, press-on caps, tamper-proof caps, aerosol over caps, inserts, ROPP caps, twist-off caps onto plastic and glass containers. Rotary cappers have much higher speed capabilities than in-line capping machines.

PLC control system, rotary type structure, the machine is with the function of automatic cap feeding, loading, and closing.

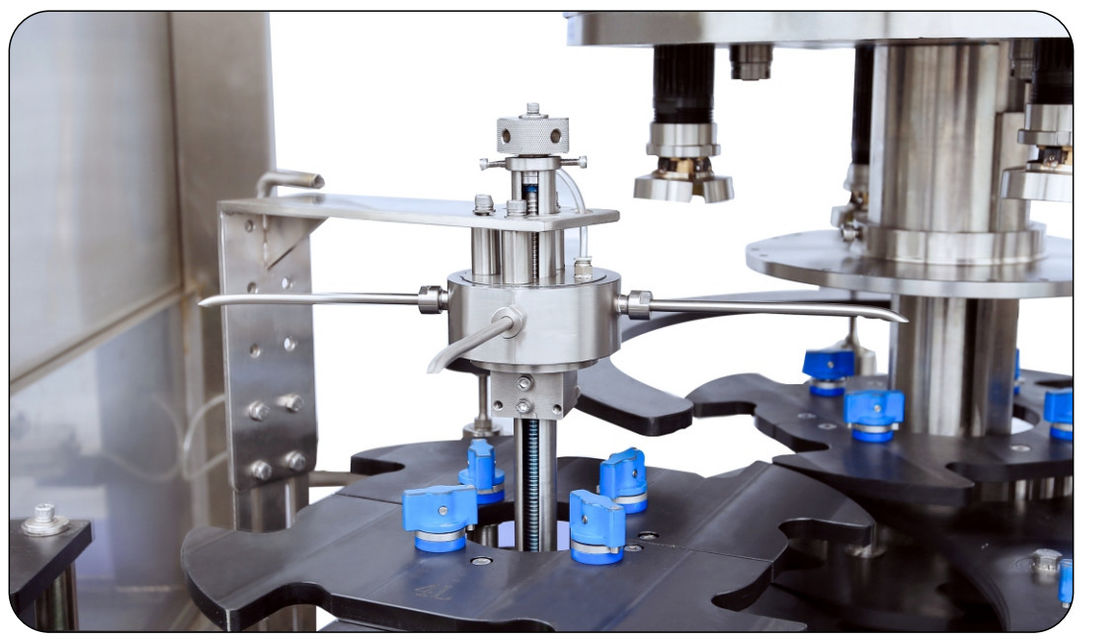

The containers are fed onto the rotary screw capper and are separated and positioned on individual capping stations. The caps are presorted and fed on the sliding table of the machine. The continuously rotating chucks are lowered over the cap to pick up and secure the caps, then apply the caps to the containers. When the preset applied torque value is achieved, the magnetic clutch disengages, the chuck releases the cap and the closed container is discharged from the machine.

With 6 mechanical hands, the model is suitable for multi-geometry containers. It dispatches caps at a fast speed without any cap reversed. Supplying cap system and mechanical hands work together in phase. When the cap is tightened, bottle and cap standstill relatively, and the clutch separates immediately so that able and not apt to be damaged.

Technical parameters:

| 1 |

Capping capacity |

6000-8000 bottles/hour |

| 2 |

Pass rate |

≥99.5% |

| 3 |

Suitable bottle size |

Φ40-95mm H80-250mm |

| 4 |

Cap size |

Φ25-60mm H20-40mm |

| 5 |

Cap heads |

6 heads |

| 6 |

Air pressure |

0.6-0.8 Mpa |

| 7 |

Power source |

~380V/50Hz/4.0KW |

| 8 |

Weight |

around 1600Kg |

| 9 |

Dimensions |

1995×1300×2246mm(L×W×H) |

Bottle Inlet Part

Capping Feeding Part

3. Detection and rejection of no aluminum foil cap

4. The cap sorter

Electric Cabinet

Key Features:

Carbon steel base mounted on adjustable floor levelers for easy alignment

Bearing frame and all surface components manufactured in 304 stainless steel

Magnetic clutch capping heads for screw caps complete with pick & place cap system

Caps in chute photocell, the machine will not work if there are no caps present on the chute

Automatic cap feeder, chute, and applicating head

Electrical socket for optional elevator feed

Safety guarding with interlock devices

Cap change parts complete set to run a different size cap(option)

Cap elevator to load the cap feeder automatically(option)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!