Fully automatic packing machine capacity is 30% higher for the automatic bottles of the bound carton

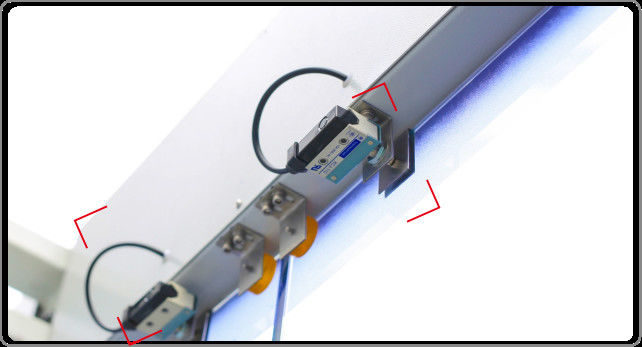

KZJ-1-type fully automatic packing machine

KZJ-1-type automatic packing machine is an improved model, using the motion controller + mechanical hand grab box, the packing process has no stop, the production capacity is 30% higher than the conventional model. This machine is suitable for the automatic bottles of the bound carton The fully automatic secondary packaging can be used in the automatic production of bottled products in the food, daily chemical, pharmaceutical, pesticide and other industries.

Process flow

Boating movement is smooth without stop, production capacity increased by 30%

, Bobottle (single automatic bottle)

, Push bottle (cylinder)

, Grab bottle (mechanical dive to complete automatic bottle)

, Lift ttle and pan (lift the bottle to the grab station)

, Bobottle (dive and bottle, complete automatic packing

Technical

| 1 |

Boacking speed |

3-7 box / min (excluding plate) |

| 2 |

Carton is applicable |

Length 250-500mm Wide 200-400mm Height 80-400mm |

| 3 |

Bottle type |

Φ40-90mm H80-260mm. |

| 4 |

Air source pressure |

0.6-0.8MPa. |

| 5 |

Power Supply / Power |

~380V 50Hz/5.5KW. |

| 6 |

Lift and down limit |

Lift the highest point to the ground level of 2700mm |

| 7 |

Machine size |

2000 × 2100 × 2120mm (L × W × H) |

| 8 |

Weight |

About 1,800 Kg |

Equipment dimension drawing:

Equipment advantages:

1, saves production costs: Save labor, improve productivity, and can replace 2-3 packing workers.

2, has a wide range of applications: suitable for plastic bottles, glass bottles, aluminum bottles, cartons and other packaging materials

3, dual servo drive mechanical starting point + imported brand movement controller, to achieve smooth bottled box action without pause, production capacity increase by 30%.

4,Easy to adjust specifications: through the replacement of different packing molds (bottle traps, suction cups, gripper, etc.), the quick assembly connection can quickly switch specifications. Provide bottle, cover and supporting carton from the Owner. We shall make packing mold according to the packing materials and carton.

5, equipment adds safety door switch, open and stop during production to protect the safety of personnel and equipment. (This function is optional)Electrical control of 6, equipment adopts imported system + French Schneider electrical components, higher capacity is more stable and reliable.

| No ial |

First name "Said that." |

Brand name |

| 1 |

Touch-screen |

Schneider.

Schneider

|

| 2 |

Converconverter |

Schneider.

Schneider

|

| 3 |

Count photoelectric |

SICK.

Schker

|

| 4 |

Close proximity switch |

LEUZE.

Labor measurement

|

| 5 |

Switch on the power supply |

Schneider.

Schneider

|

| 6 |

Pressure switch |

SMC. |

| 7 |

Cylinder |

FTEC.

Eptai

|

| 8 |

Solenoid valve |

FTEC.

Eptai

|

| 9 |

Button |

Schneider.

Schneider

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!