Weighing-Type Fully Automatic Filling Machine Automatic Weighing And Filling Of Foam

CZ-6G weighing-type fully automatic filling machine

General information:

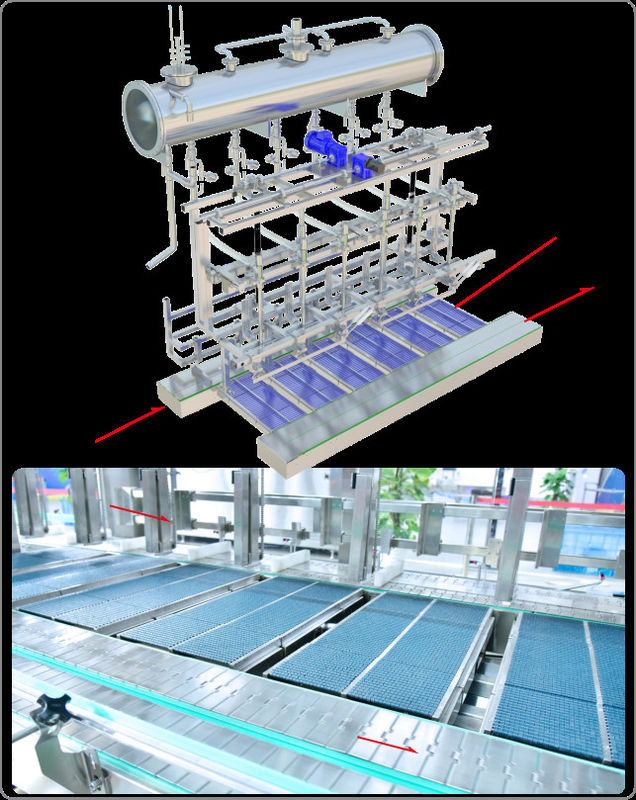

CZ-6G weighing automatic filling machine consists of bucket delivery, weighing filling unit, bucket delivery, fast, slow filling (with motor diving) mechanism, feed transition box, weighing control instrument and programmable control unit. The liquid filling scale can meet the needs of automatic weighing and filling of foam.

Technical parameters:

| 1 |

Fill speed |

≤ 600 barrel / h (20Kg) (with water as the medium) |

| 2 |

Measurement accuracy |

± 0.2% (Water as the medium) |

| 3 |

Bottle type |

Minimum of 200 × 140 × 320mm Maximum 290 × 260 × 400mm (L × W × H) |

| 4 |

Fill range |

5-30Kg. |

| 5 |

Feed pipe diameter |

DN40. |

| 6 |

Feed port height |

3250mm. |

| 7 |

Air source pressure |

0.6-0.8MPa. |

| 8 |

Power Supply / Power |

~380V 50Hz/2.6KW. |

| 9 |

Overall dimensions |

4700 × 2390 × 3685mm (L × W × H) |

| 10 |

Weight |

Approximately 1,500 Kg |

Equipment dimension drawing:

Equipment advantages:

1, capacity: three-row structure (entering barrel, weighing and filling, discharging barrel) to save time and improve the production capacity;600 barrels / h (20L for example).

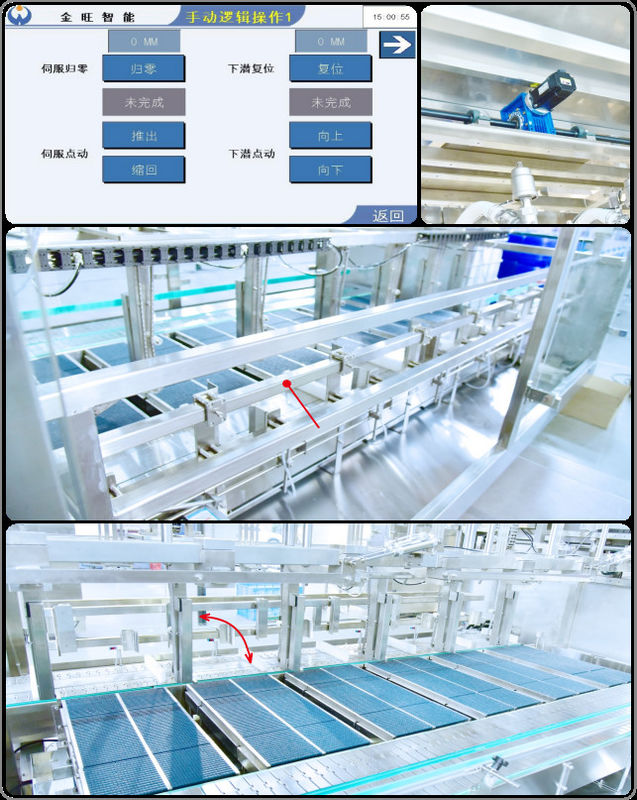

2, switch adjustment fast: replace the specifications only need to input the size in the touch screen, use the servo motor + plus putter to locate the barrel port; not the traditional cylinder bottle positioning barrel port needs tool adjustment, this way adjustment needs no tools, one button adjustment in the procedure is quick and convenient.

3, visual circular material box, the situation is clear at a glance, circular material warehouse design, cleaning completely without material.

4, high accuracy: using the weighing filling system (Mettler-Toledo METTLER TOLEDO weighing sensor) to ensure the high accuracy of filling measurement.

5, uses fast and slow filling valve motor filling under the diving liquid surface, effectively solving the problem of material foam.

6, electric control system adopts French Schneider configuration, integratedelectric control system, more stable, reliable, safe and low energy consumption.

7, contact material adopts 304 stainless steel material, to better adapt to various production environment, good anti-corrosion performance and easy cleaning. The sealing material of the material is PTFE.

8, outsourcing stainless steel and tempered glass door cover seal the body, and the exhaust outlet (nozzle aperture is Φ120mm diameter) can be connected to the factory air introduction system to discharge the exhaust gas from the filling process.

Main configuration of the equipment:

| No ial |

First name "Said that." |

Brand name |

|

1

|

Weing sensor

|

METTLER TOLEDO.

Mettololedo

|

|

2

|

Programmable controller

CPU.

|

Schneider.

Schneider

|

| 3 |

Touch-screen |

Schneider.

Schneider

|

| 4 |

Converconverter |

Schneider.

Schneider

|

| 5 |

Servo system |

Schneider.

Schneider

|

| 6 |

Count photoelectric |

SICK.

Schker

|

| 7 |

Close proximity switch |

Leuze.

Labor measurement

|

| 8 |

Switch on the power supply |

Schneider.

Schneider

|

| 9 |

Pressure switch |

SMC. |

| 10 |

Cylinder |

FTEC.

Eptai

|

| 11 |

Solenoid valve |

FTEC.

Eptai

|

| 12 |

Button |

Schneider.

Schneider

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!