CDP-12AS-type microcomputer in-line filling machine

General information:

CDP-12AS microcomputer direct filling machine is suitable for filling of pesticide water and emulsion. The whole machine is an in-line structure, using the measurement and filling principle of maintaining constant liquid level (fixed speed) and timing mode to achieve accurate filling. PLC control, touch human-machine interface, convenient and intuitive operation. The high-precision electronic scale automatic weighing data transmission system is selected, and the dose adjustment is faster.

Technical parameters:

| 1 |

Fill speed |

100ml Bottle ≤ 5,000 bottles / h 500ml Bottle ≤ 2,800 bottles / h

1000ml bottle ≤ 2000 bottles / h (* With water as the medium, the actual capacity fluctuates up and down depending on the customer material)

|

| 2 |

Bottle type |

Round bottle: Φ40-95mm in diameter Bottle height is 80-230mm |

| 3 |

Measurement accuracy |

± 1g (50mL) ± 3g (1000mL) (* water as medium) |

| 4 |

Feed port height |

2300mm. |

| 5 |

Feed port diameter |

Φ35mm. |

| 6 |

Outer diameter of the lower feeding mouth |

Φ12mm. |

| 7 |

Corresponding to the minimum bottle mouth inner diameter |

≥ Φ16mm. |

| 8 |

Diving trip |

100mm. |

| 9 |

Air source pressure |

0.6-0.8MPa. |

| 10 |

Power Supply / Power |

~380V 50Hz/0.7KW. |

| 11 |

Overall dimensions |

1995 × 700 × 2500mm (L × W × H) |

| 12 |

Weight |

About 550Kg |

Main configuration of the equipment:

| No ial |

First name "Said that."

|

Brand name

|

|

1

|

Programmable controller

CPU.

|

Schneider.

Schneider

|

| 2 |

Touch-screen |

Schneider.

Schneider

|

| 3 |

Converconverter |

Schneider.

Schneider

|

| 4 |

Connecting rod floating ball level controller |

ZERO.

Zeno

|

| 5 |

Count photoelectric |

SICK.

Schker

|

| 6 |

Switch on the power supply |

Schneider.

Schneider

|

| 7 |

Pressure switch |

SMC. |

| 8 |

Cylinder |

FTEC.

Eptai

|

| 9 |

Solenoid valve |

FTEC.

Eptai

|

| 10 |

Button |

Schneider.

Schneider

|

| 11 |

Warning lamp |

Schneider.

Schneider

|

| 12 |

Circuit breaker |

Schneider.

Schneider

|

Equipment dimension drawing:

Equipment advantages:

1, is widely used in the automatic filling of 80-1000mL bottles in pesticides, fine chemicals, daily chemicals, fertilizers, oils and other industries.

2, electronic weighing system, dose adjustment with one button. (This function is optional)

3, complete electric control system adopts French Schneider configuration, integrated electric control system, more stable, reliable, safe and low energy consumption.

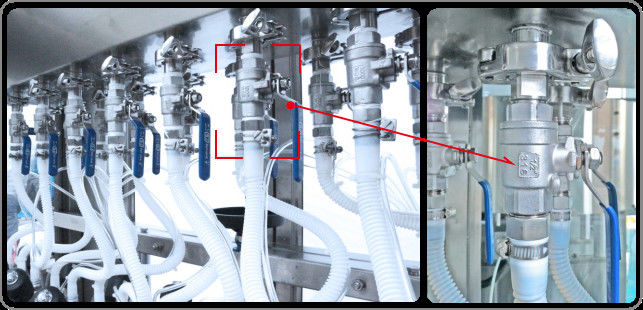

4, is controlled by German German valve, and the filling dose is more stable, durable and reliable. Similar products on the market are in general Use the domestic corner seat valve control, poor stability and durability.

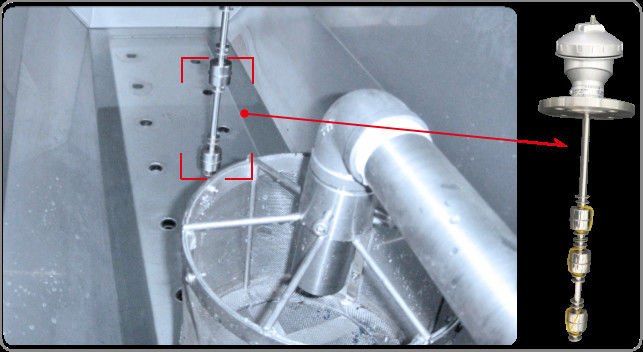

5, material box is quick assembly for convenient cleaning and maintenance. The manual ball valve is made of 316 for longer service life.

6, feed pipe is equipped with a removable filter screen to prevent the filling valve from affecting the filling accuracy and valve service life due to impurities. In addition to the use of normal operating liquid level control, high and low liquid level detection and acoustic and optical alarm devices shall be added to prevent abnormal liquid level.

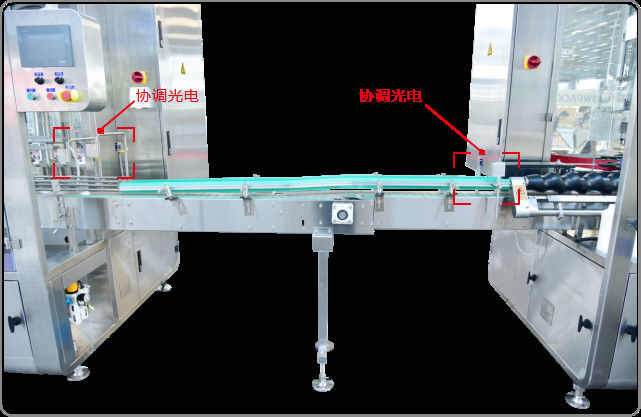

7, filling machine is short of bottles, and the filling machine and the rear side are equipped with coordinated photoelectric. When the bottle is not blocked, it automatically realizes the linkage function with the rear equipment.

8, whole machine adopts high quality SUS304 stainless steel, good anticorrosion performance, outsourcing stainless steel and tempered glass door cover to seal the body, to better adapt to the agrochemical production environment. The exhaust outlet (nozzle bore of Φ 120mm diameter which is reserved at the filling head) can be connected to the factory air diversion system to discharge the exhaust gas from the filling process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!