DGD-220B 40 bags/minute Automatic Horizontal Preformed Pouch Packing Machine

Introduction:

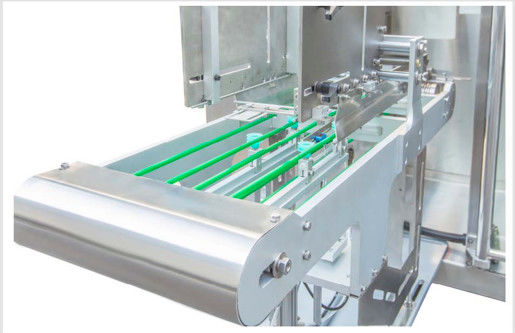

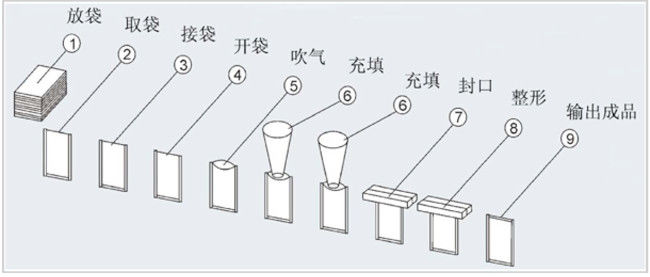

DGD-220B Automatic Horizontal Pouch Packing Machine includes the pouch feeding structure, pouch opening, blowing, filling, sealing and pouch flattening structure. With the mechanical connecting rods and high precision imported cam indexers to complete each movement and the encoder on the main axis feedback the position signal. Under the control of the PLC, it can realize pouch feeding-pouch opening-inspecting-filling-sealing-finished products. The finished products can be packed into cartons. The machine is with the features of reasonable design, good looking and large organic glass cover can meet the production requirements of safe and environmental friendly. Different products filling can be realized on the machine by changing different feeding devices, both for powder, granule, liquid and SC filling. It can be widely used for the production of pre-formed pouches.

Features:

1. Environmental Friendly: The machine is with closed design, the dust inside the machine can not going out, it can equipped with SUS dusting system, without pollution (SUS dusting system is an option)

2. Intellectual: It is equipped with laser dusting alarm device, it monitors the dust situation inside the machine, the control fan can absorb the dust, it is with the features of high effective, intellectual and environmental friendly. (Intellectual dust alarm system is an option)

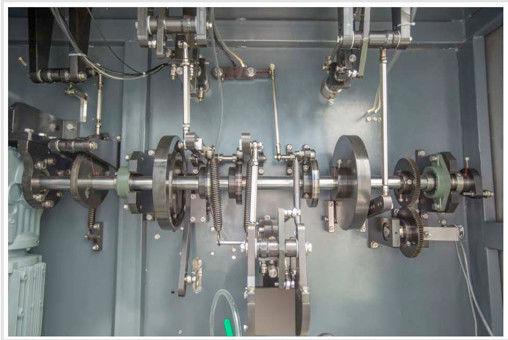

3. Easy Maintenance: The new heating blocks structure is easy for cleaning and maintenance.

4.Cost Saving: The bag opening inspecting function can realize no bag, no filling and sealing, so the sachets can be used again without any waste.

5. Stable: We change the single clamp into double clamps, this can make sure the sachet conveying more stable.

6. Spanish Cam technology, we use the internal cams and cancels the pull spring structure; this will make sure the high precision of operation.

7. Upgraded sachet feeding structure, it will reduce the frequency of adding pouches; it can place about 600 sachets, this can improve the production efficiency.

Technical Parameters:

| Model |

DGD-220B |

| Capacity |

40-55 pouches/min |

| Pouch Width |

100-215mm |

| Pouch Height |

140-330mm |

| Air Pressure |

0.6MPA |

| Power Source |

3 Phase, AC380V, 50HZ, 3.5KW |

| Material |

SS304 |

Allocations:

| NO. |

Name |

Brand |

Remarks |

| 1 |

Touch Screen |

Schneider |

|

| 2 |

Inverter |

Schneider |

|

| 3 |

PLC |

Schneider |

|

| 4 |

Power Switch |

Sunon |

|

| 5 |

Encoder |

Omron |

|

| 6 |

Intermediate Relay |

Schneider |

|

| 7 |

Pneumatic Parts |

Airtac |

|

| 8 |

Contactor |

Schneider |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!