DGD-330 automatic horizontal bag bag machine

General information:

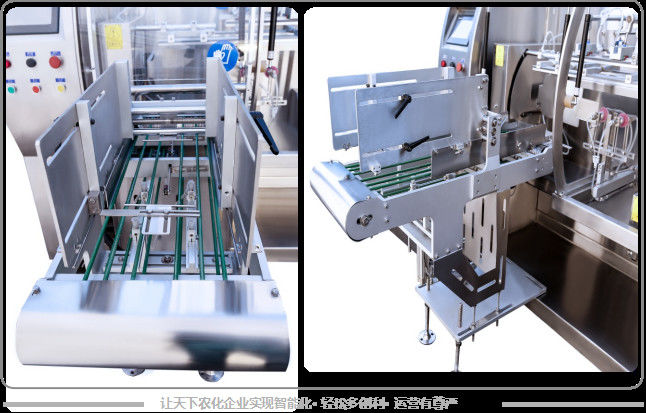

DGD-330 automatic horizontal bag bagging machine includes bag picking mechanism, bag opening mechanism, blowing mechanism, blowing mechanism, bag opening testing mechanism, filling mechanism, hot sealing, cold sealing and other institutions. Complete the coordination operation of each mechanism through the high-precision inlet cam splitter, and feedback the position signal from the encoder on the main shaft. Under the programmable control of PLC, the function of detecting → with → sealing → is realized. The machine has reasonable design, novel appearance, large area arc organic glass door, to meet the production requirements of safety and environmental protection. At the same time, the powder, particles, water agent, suspension agent and other materials can be automatically filled on the machine. Suitable for the packaging and production of various prefabricated bag products.

(The main machine is shown as a 50 L powder filling device, which is optional)

Technical parameters:

| 1 |

Production capacity |

20-40 Package / Sub-Sub * Actual capacity depends on the packaging material |

| 2 |

Suitable for the bag type |

W150-315mm. L200-480mm. |

| 3 |

Packaging capacity |

The ≤ 1000g * is determined by the material weight and package size |

| 4 |

Fill accuracy |

± 1% (depending on the material condition) |

| 5 |

Power Supply / Power |

Three-phase AC380V 50Hz/6.0KW |

| 6 |

Air source pressure |

0.5-0.7MPa. |

| 7 |

Equipment dimensions |

3650 × 2035 × 1500mm (L × W × H) * No packing device included |

| 8 |

Dust removal pipe diameter |

Φ98mm. |

| 9 |

Complete machine weight |

Approximately 3,200 Kg |

Equipment dimension drawing:

Equipment advantages:

1, This equipment is mainly used in the production of various prefabricated bags, beautiful packaging molding; good forming; almost no packaging materials and material waste.

2,'s unique open bag detection function: no open bag, no filling, not hot seal, the bag can be used again, do not waste materials, and save the production cost for users.

3, large capacity bagging mechanism: when the equipment operation, reduce the bagging frequency, improve the production efficiency.

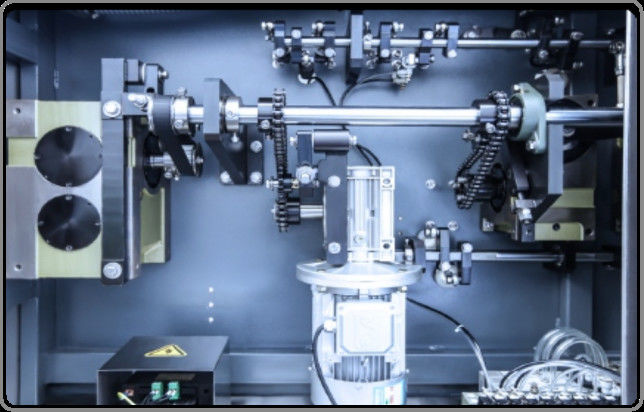

4, uses Taiwan original imported cam splitter, making the drive high precision, stable and reliable.

5, exquisite parts processing process: exquisite design process plus imported parts machining of CNC center, high precision and high standard,

Ensure the stability and durability of each part.

6,The uses an integrated control system tailored to French Schneider Electric, with high compatibility, high stability, and lower energy consumption.

7, intelligent temperature control system: monitor the temperature changes through touch display, so as to effectively control the thermal sealing mechanism, ensure the reliability of the sealing, with its own plastic shaping mechanism will further improve the beauty of the bag, so that the packaging products are good and good.

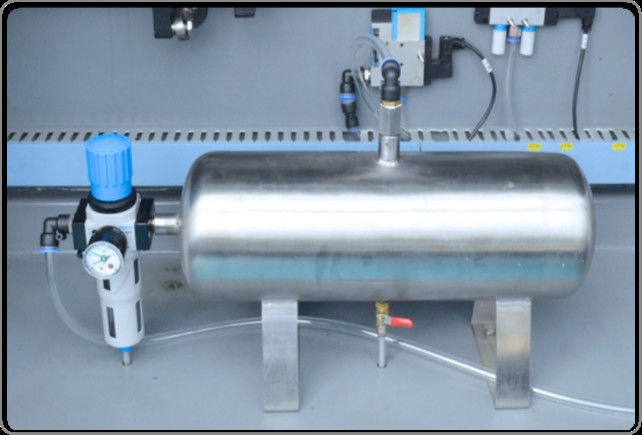

8, has a small gas storage tank to reduce the impact of external pressure fluctuations on the bag and opening. The air supply pressure detection system is also standard.

9, multiple safety protection (Japanese SMC vacuum generator, gas source processor with air pressure detection, etc.), for maximum protection

Verify the stability and reliability of the equipment operation.

Main configuration of the equipment:

| No ial |

First name "Said it." |

Product Card |

|

1

|

Programmable controller

CPU.

|

Schneider.

Schneider

|

| 2 |

Touch-screen |

Schneider.

Schneider

|

| 3 |

Converconverter |

Schneider.

Schneider

|

|

4

|

Servo system

|

Schneider.

Schneider

|

| 5 |

Approach sensor |

Sick.

Schker

|

| 6 |

Switch on the power supply |

Schneider.

Schneider

|

| 7 |

Vacuum generator |

SMC. |

| 8 |

Heat fan |

SUNON.

Completion permit

|

| 9 |

Encoder |

OMRON.

The Omron

|

| 10 |

Button |

Schneider.

Schneider

|

| 11 |

Circuit breaker |

Schneider.

Schneider

|

| 12 |

Pressure switch |

SMC. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!