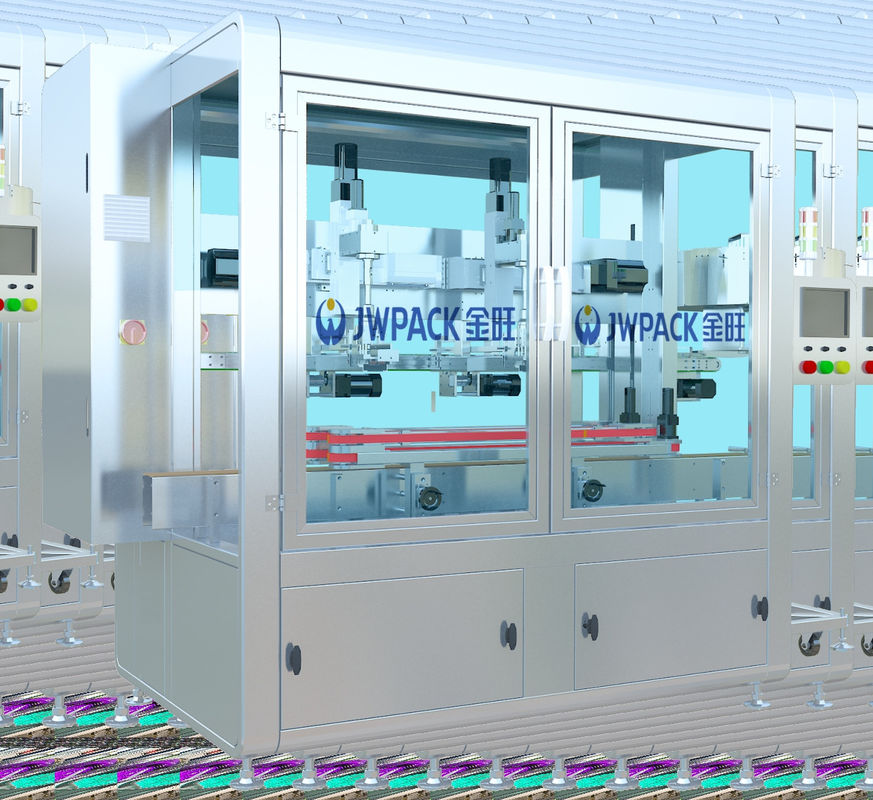

Automatic Double-Follow Rotary Machine Newly Developed Keep The Bottle Clean Simple Structure And Easy Adjustment

FXG-2E automatic double-follow rotary machine

General information:

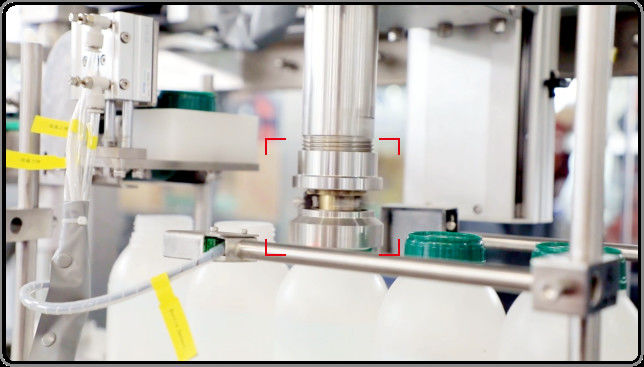

FXG-2E automatic double-head follow cover machine consists of cover transmission mechanism, grab cover cover mechanism, motion module, conveying mechanism and control system. The whole machine has a simple structure and easy adjustment.This equipment is newly developed by our company and complete the cover rotation during moving. Different from the conventional cover machine, it needs to stop when spinning the cover, which will shake the material out of the bottle mouth and pollute the bottle body. The machine cover does not stop, effectively avoid the cover stop shaking liquid, keep the bottle clean.

Bottle type

Automatic rock cover and rotary cover for 50-1000ml various round bottles, square bottles and flat bottles

Technical parameters:

| 1 |

Production capacity |

≤ 5,500 bottles / h (100mL, for example) |

| 2 |

Qualified rate |

≥99% |

| 3 |

Bottle type |

Diameter of Φ40-90mm Height of 80-230mm

Square bottle is 45-110mm long Width of 45-60mm High of 80-230mm

|

| 4 |

Bocap specifications |

Diameter Φ25-60mm, cover is 20-40mm high |

| 5 |

Air source pressure |

0.6~0.8MPa. |

| 6 |

Power supply |

~380V,50Hz. |

| 7 |

Power supply |

7.0KW. |

| 8 |

Weight |

1500Kg. |

| 9 |

Overall dimensions |

2200 × 1440 × 2300mm (L × W × H) |

Equipment dimension drawing:

Equipment advantages:

1, versatility: automatic cover for 50-1000ml;

2, quality: follow the rotary cover, do not stop the rotary cover process, do not shake liquid, do not pollute the bottle mouth, bottle body and conveyor belt, to ensure the qualified rate of aluminum foil sealing;

3, switching specifications are simple and low maintenance cost: just replace the rotary cover head of different specifications, and complete the quick switch in 10 minutes; all vulnerable parts are clear at a glance;

4, High qualified rate: use the servo motor to control the rotary cover torque, and make the digital torque adjustment in the touch screen.

5, uses Festow brand electric drive elements, stable and efficient.Capacity: ≤ 5,500 bottles / h. And the peer uses the self-made screw lifting mechanism, the accuracy cannot be guaranteed

6, adopts the servo motor controlled belt split bottle, making the barrel positioning more accurate, to ensure the high qualified rate of rotary cover.

7, governor is quick, 15 minutes: conventional cover requires at least 0.5-1 hour to adjust the specification.Electrical adjustment is completed with one key and set directly in the touch screen.

8, high-end electric control system: all electrical components of the whole machine are French Schneider brand, and all electric drive components are German Festor brand, stable and efficient.

Main configuration of the equipment:

| No ial |

First name "Said that." |

Brand name |

|

1

|

Programmable controller

CPU.

|

Schneider.

Schneider

|

| 2 |

Touch-screen |

Schneider.

Schneider

|

| 3 |

Converconverter |

Schneider.

Schneider

|

| 4 |

Servo system |

Schneider.

Schneider

|

| 5 |

Count photoelectric |

SICK.

Schker

|

| 6 |

Switch on the power supply |

Schneider.

Schneider

|

| 7 |

Pressure switch |

SMC. |

| 8 |

Electric cylinder |

FESTO.

Festow

|

| 9 |

Button |

Schneider.

Schneider

|

| 10 |

Warning lamp |

Schneider.

Schneider

|

| 11 |

Circuit breaker |

Schneider.

Schneider

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!