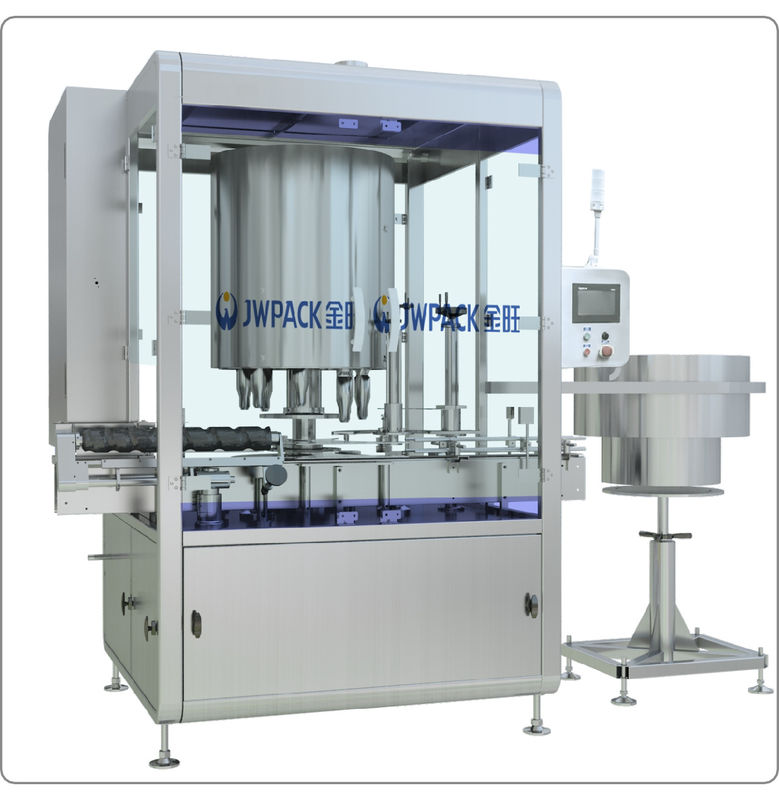

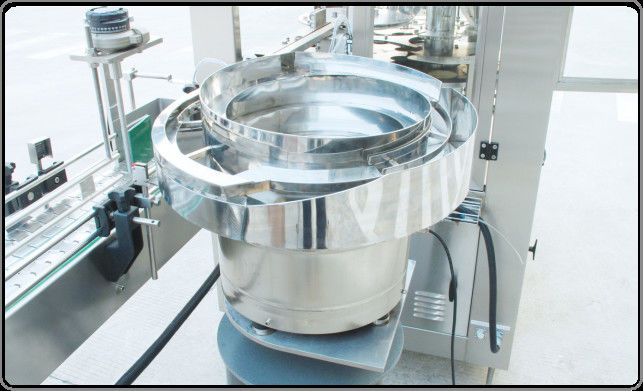

Fully Automatic Cover Press Rotary Structure Transported By The Scraping Cover Plate Inner Cover Bottle Rotation Process

YG-10DS fully automatic cover press

General information:

This machine is suitable for automatic compression of glass or plastic bottles. The whole machine is a rotary structure, with the vacuum suction nozzle absorbing various inner plugs transported by the scraping cover plate, and closing the inner cover during the bottle rotation process. The whole machine adopts PLC control, touch-type human-machine interface, convenient and intuitive operation.

Bottle type

It is widely used in pesticide, fine chemical, 80-1000mL bottles of automatic press internal plug cover, daily chemical, fertilizer, oil and other industries

Technical parameters:

| 1 |

Production capacity |

≤ 8,000 bottles / hour (100mL, for example) |

| 2 |

Qualified rate |

≥99.8% |

| 3 |

Bottle type |

Φ40-95mm. H80-230mm. |

| 4 |

Inner plug specifications |

Φ15-30mm. H10-15mm. |

| 5 |

Number of cover heads |

Ten items |

| 6 |

Air source pressure |

0.6~0.8MPa. |

| 7 |

Power supply |

~380V 50Hz. |

| 8 |

Power supply |

4.0KW. |

| 9 |

Weight |

1600Kg. |

| 10 |

Overall dimensions |

1995 × 1445 × 2344mm (L × W × H) |

Equipment dimension drawing:

Equipment advantages:

1, machine adopts rotary structure, vacuum nozzle suction plug, stable and reliable.

2, The electric control system adopts French Schneider configuration, and the integrated electric control system is more stable and reliable, safe, green and low energy consumption.

3, The machine is based on safe production:

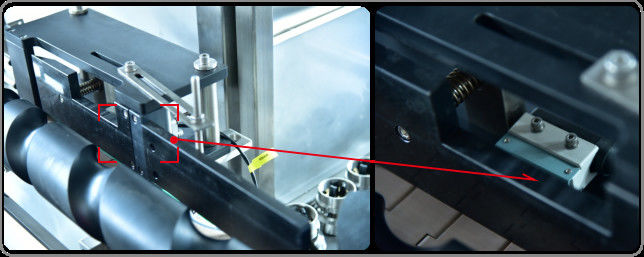

. Equipped with reverse and jam detection switches, and the equipment will stop automatically when reverse or jam occurs, so as not to damage the twist or star wheel.

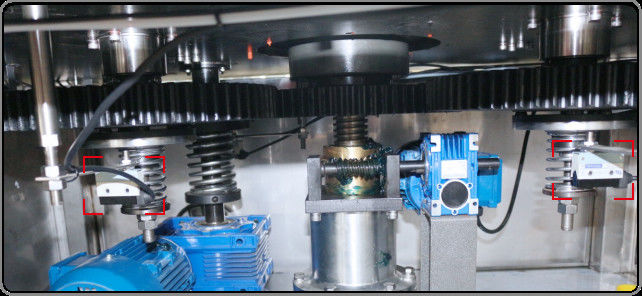

Clutch limit protection switch is equipped with all transmission parts, which will automatically leave the combined shutdown alarm of the main shaft, protect the equipment from damage and improve the service life.No other similar gland presses are available on the market.

4, humanized design: refer to the design structure of AROL(Claus spin cover, the global top rotary cover manufacturer), supporting automatic motor lifting (touch screen or point button) + semi-automatic handle lifting adjustment mode, convenient and quick to adjust the specifications. At present, the similar rotary cover machine on the market can only be adjusted manually either, without automatic lifting function or triangle belt transmission, and no manual lifting without electricity, and the adjustment is more cumbersome.

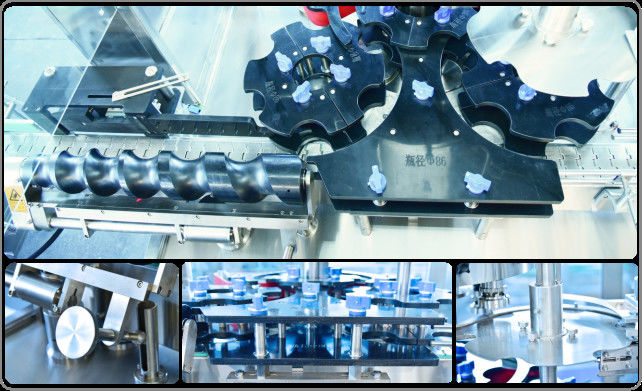

5, quick loading tooling design, no tool replacement, and tool carving logo according to different bottle types. It is more convenient and fast to replace the bottle type specifications, and the bottle type switching time can be shortened to 10 minutes.

6, independent internal plug system, unique design, anti-inner plug automatically flow back into the inner plug barrel, to ensure that the delivered inner plugs are all positive inner plug.

7, has no internal plug delay automatic shutdown protection function (when running, check the inner plug photoelectric can not detect the internal plug for a long time, automatically stop and alarm, to ensure normal production).

Main configuration of the equipment:

| No ial |

First name "Said that." |

Brand name |

| 1 |

Programmable controller

CPU.

|

Schneider.

Schneider

|

| 2 |

Touch-screen |

Schneider.

Schneider

|

| 3 |

Converconverter |

Schneider.

Schneider

|

| 4 |

Count photoelectric |

SICK.

Schker

|

| 5 |

Switch on the power supply |

Schneider.

Schneider

|

| 6 |

Pressure switch |

SMC. |

| 7 |

Cylinder |

FTEC.

Eptai

|

| 8 |

Solenoid valve |

FTEC.

Eptai

|

| 9 |

Button |

Schneider.

Schneider

|

| 10 |

Circuit breaker |

Schneider.

Schneider

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!