Rocking Arm Ton Barrel Filling Machine Controller Outputs Fast Various Liquids Foam-Free And Foam Liquid

CC-1000 rocking arm ton barrel filling machine

General information:

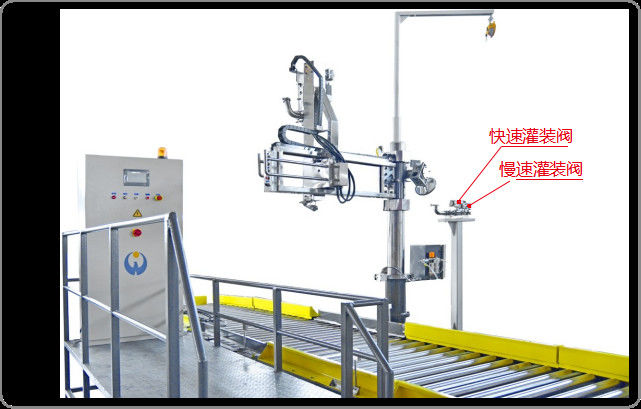

The CC-1000 rocker arm ton-barrel filling machine monitors the current filling volume in real time and feeds it back to the controller. The controller outputs fast and slow filling control signals according to the set data to realize the fast and accurate filling of large filling specifications. The equipment can meet the needs of automatic filling of various liquids and meet the filling of foam-free and foam liquid.

Technical parameters:

| 1 |

Maximum weighing |

1500Kg. |

| 2 |

Degree value |

200g. |

| 3 |

Fill accuracy |

±0.2% |

|

4

|

Fill speed

|

200L:35-45 barrel / h

1000L:5 barrel / h

(* Actual filling speed depends on the feeding speed and operation proficiency of the material)

|

| 5 |

Material temperature |

Normal temperature |

| 6 |

Measurement device |

1200 × 1200 × 90mm. |

| 7 |

Maximum tray size |

1200 × 1200 × 150mm. |

| 8 |

Applicable ambient temperature range |

0-40℃ |

| 9 |

Relative humidity |

56-78%, free of condensation |

| 10 |

Power Supply / Power |

~380V 50Hz/1.55KW. |

| 11 |

Air source pressure |

0.6-0.8MPa. |

| 12 |

Material pressure |

≤ 0.2MPa. |

| 13 |

Feed port height |

1700mm. |

| 14 |

Inlet inlet pipe diameter |

φ44mm. |

| 15 |

Outer diameter of the filling head |

φ48mm. |

| 16 |

Corresponding to the barrel opening diameter |

≥ φ58mm. |

| 17 |

Overall dimensions |

1615 × 2330 × 4000mm (L × W × H) |

| 18 |

The column of the filling machine shall be fixed to the ground with expansion screws |

Equipment dimension drawing:

Equipment advantages:

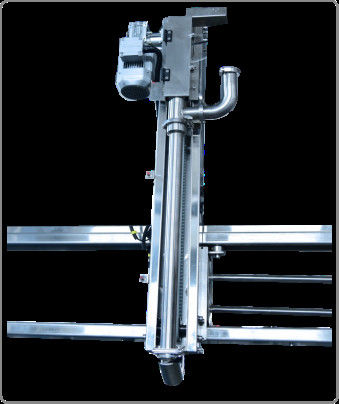

1, covers a small area, compact structure, simple to use, only one person operation, save labor.

2.High accuracy: weighing filling (Metler-Toledo METTLER TOLEDO weighing sensor) to ensure the high accuracy of filling measurement.

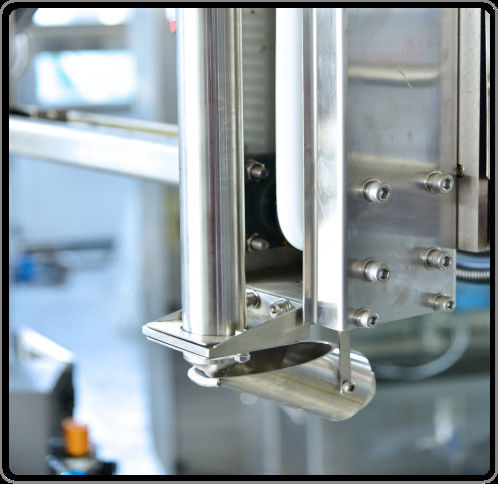

3,The filling head adds the rotating liquid cup to collects the remaining materials on the filling head to prevent material leakage from polluting the bottle mouth.

4, adopts fast and slow filling to ensure the measurement accuracy and speed.

5, dive filling head to avoid material splash.

6, automatic diagnosis, automatic fault alarm function, and improve the reliability of the system operation.

7, skin redetection to detect whether the container on the counter is pair or has material in the container.

8, anti-collision barrel alarm: spray gun alignment detection, collision barrel alarm, safer.

9, self-locking control: Before filling, operate the swing arm through the button to align the barrel mouth, lock the barrel mouth automatically, and the filling can be allowed after detecting that the injection gun is in place.

10, The whole machine adopts the latest Schneider electric control system for stable control and relative low power consumption.

Main configuration of the equipment:

| No ial |

First name

|

Brand name

|

| 1 |

Weing system |

METTLER TOLEDO.

Mettler-Toledo

|

| 2 |

Programmable controller

CPU.

|

Schneider.

Schneider

|

| 3 |

Touch-screen |

Schneider.

Schneider

|

| 4 |

Converconverter |

Schneider.

Schneider

|

| 5 |

Count photoelectric |

SICK.

Schker

|

| 6 |

Close proximity switch |

LEUZE.

Labor measurement

|

| 7 |

Pressure switch |

SMC. |

| 8 |

Solenoid valve |

FTEC.

Eptai

|

| 9 |

Button |

Schneider.

Schneider

|

| 10 |

Warning lamp |

Schneider.

Schneider

|

| 11 |

Circuit breaker |

Schneider.

Schneider

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!