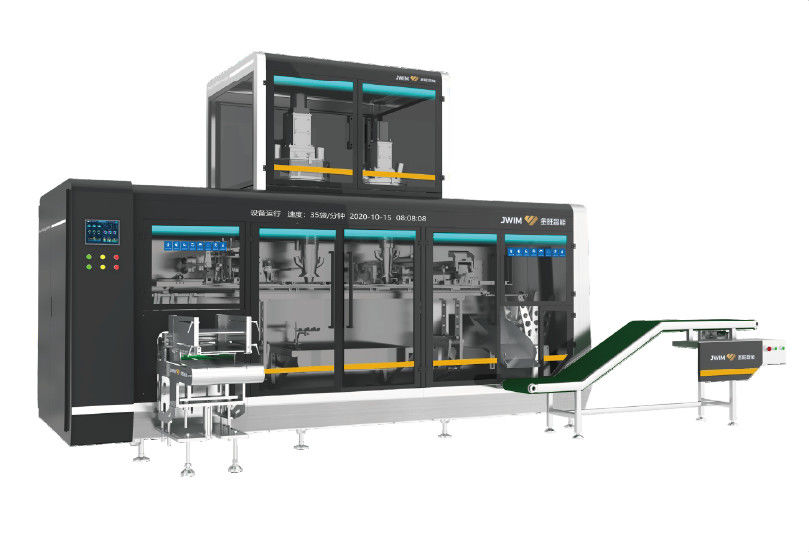

45bags High-speed Auto Pouch Packing Machine Standing Pouch Sealing Machine 100g 1000g

1. Description of the Granule Automatic Pouch Packing Machine

DGD-280AM full-automatic horizontal bag feeding bagging machine is our in-line online weighing bagging machine, which can be equipped with an online weighing and filling function and vacuum pumping function.

The whole machine includes a bag-taking mechanism, bag opening mechanism, air blowing mechanism, filling mechanism, heat sealing, cold sealing, and shaping mechanism.

The coordinated action of each mechanism is completed through the mechanical connecting rod and cam structure.

Under the programmable control of PLC, the functions of bag-taking → bag opening → detection → filling → sealing → finished product are realized. The machine has a reasonable design, novel appearance, and complete dust removal system, which meets the production requirements of safety and environmental protection.

At the same time, by changing the filler, the automatic filling of powder, particle, water agent, suspension agent, and other materials can be realized on the machine. It is applicable to the packaging production of all kinds of prefabricated bag products.

2. Parameters of the Granule Automatic Pouch Packing Machine

| Productive Power. |

15-45bags / min |

| Applicable Bag Size |

W120-280mm L180-380mm |

| Packaging Capacity |

≤1000g |

| Filling Precision |

±1g(100g);≤±2g(200-300g);≤±3g(300-500g);≤±3g(500-1000g) |

| Air Pressure |

0.5-0.7MPA 500L/min |

| Power |

AC380V 50Hz/5.5KW |

| Equipment Size |

3350×2500×2800mm(L×W×H) |

3. Advantages of the Granule Automatic Pouch Packing Machine

a) The equipment is suitable for the production of all kinds of prefabricated bags, with beautiful packaging and molding.

b) The operation status (data) of the whole line is presented in real-time (at a glance).

c) Cost saving: unique bag opening detection function, no bag opening, no filling, no heat sealing, the bag can be reused without wasting materials.

d) Environmentally friendly: a material collection tank is added under the blanking device of the host machine, convenient for manual cleaning and material recycling.

e) Easy maintenance: Upturnable ironing block structure, convenient for maintenance and cleaning.

f) The integrated control system customized by Schneider Electric of France is adopted, which has good compatibility, high stability, and lower energy consumption.

g) Multiple safety protection (Japanese SMC vacuum generator, air source processor with air pressure detection, etc.) to ensure the stability and reliability of equipment operation to the greatest extent.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!