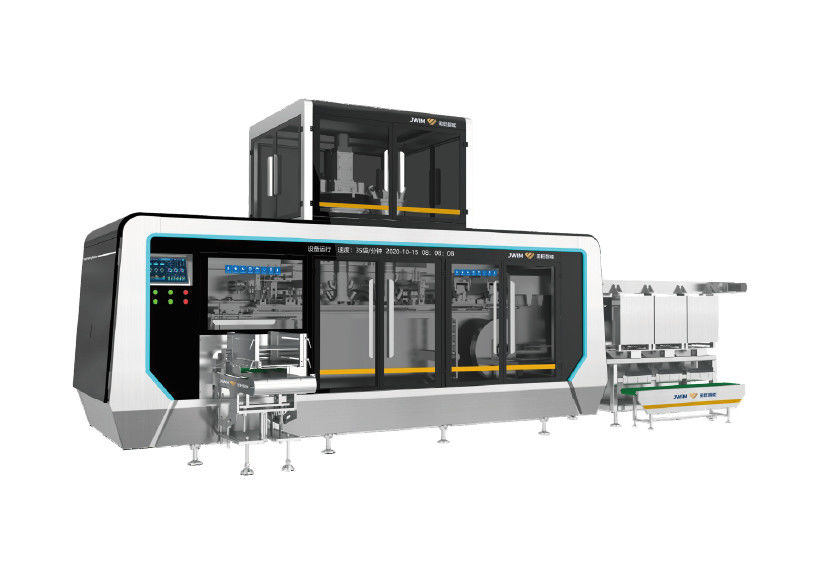

≤1000g/6.0kw/Powder/Prefabricated Bag/Weighing Mod Mace/Granule Automatic Pouch Packaginghine(DGD-310AH)

1.Description/ Introduction

DGD-310AH full-automatic horizontal bag feeding bagging machine is our in-line online weighing bagging machine, which can be equipped with online weighing and filling function and vacuum pumping function. Under the programmable control of PLC, the functions of bag taking → bag opening → detection → filling 1 (degassing) → filling 2 (weighing) → sealing → vacuum pumping → finished product are realized. The machine has reasonable design, novel appearance and complete dust removal system, which meets the production requirements of safety and environmental protection. At the same time, by changing the filler, the automatic filling of powder, particles and other materials can be realized on the machine. It is applicable to the packaging production of all kinds of prefabricated bag products.

2.Parameters / specifications

| Productive Power. |

15-45bags / min |

| Applicable Bag Size |

Minimum bag: 150 × 200mm, max. bag: 310 × 400mm |

| Packaging Capacity |

≤1000g |

| Filling Precision |

±1g(100g);≤±2g(200-300g);≤±3g(300-500g);≤±3g(500-1000g) |

| Air Pressure |

0.6-0.8MPA 500L/min |

| Power |

AC380V 50Hz/6.0KW |

| Equipment Size |

3995×2500×2560mm(L×W×H) |

3.Features

(a)High speed railway has high appearance grade and high visibility; The operation status (data) of the whole line is presented in real time (at a glance).

(b)The equipment is suitable for the production of all kinds of prefabricated bags, with beautiful packaging and molding; Almost no waste of packaging materials and materials.

(c)The production capacity is 30% faster than that of the linear type, and the maintenance speed is higher than that of the linear type.

(d)High precision: rough filling and weighing filling (filling while weighing) are adopted to ensure the high precision of products( This function is optional).

(e)Mechanical bag opening auxiliary + mechanical bag opening detection double insurance to ensure no leakage of materials.

(f)Easy maintenance: Upturnable ironing block structure, convenient for maintenance and cleaning.

(g)Vacuum pumping mechanism (micro vacuum) in the bag wiping station to reduce dust and material volume before sealing.

(h)The Spanish internal CAM technology driven by connecting rod driven by servo motor is adopted, which does not run and has higher operation accuracy. It can stop the spindle during filling.

(i)Improve the filling function: bottom filling, reduce a lot of dust and purify the operation and production environment. At the same time, ensure that more materials can be filled with the same packaging size.

(j)More environmentally friendly: a material collection tank is added under the blanking device of the host machine (convenient for manual cleaning and material recycling).

(k)Optimize the bag taking structure, prolong the bag suction time and take the bag more accurately; At the same time, the large capacity bag placing mechanism can store about 300 bags at most, reduce the bag placing frequency and improve the production efficiency when the equipment is running.

(l)More durable: exquisite design technology and parts processing of imported CNC center, high precision and high standard ensure the stability and durability of each part.

(m)Temperature control integrated module: real-time monitoring of temperature changes, touch screen operation control, at a glance, to ensure the stability and reliability of equipment operation to the greatest extent.

(n)The integrated control system customized by Schneider Electric of France is adopted, which has good compatibility, high stability and lower energy consumption

(o)Multiple safety protections (phase sequence protector, air source processor with air pressure detection, etc.) ensure the stability and reliability of equipment operation to the greatest extent.

(p)It is equipped with a small vacuum pump to reduce the impact of external air pressure fluctuation on bag loading and bag opening.

(q)Vacuum pumping and sealing function: all the air in the bag is pumped out and sealed to maintain a high decompression state in the bag, which can effectively reduce the packaging volume, packaging cost and transportation cost( This function is optional)

(r)The equipment of the filling device for powder, water agent, viscosity agent, granule and so on is reserved on the equipment, and the software is also reserved. The user only needs to install the connector when changing the filling device, and the function can be used in the touch screen.

(s)It can be equipped with belt climbing transportation to transport the packaging materials of finished products to the next process or pack them manually.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!