≤200ml (single bag); ≤100 × 2 = 200 ml (double bag)/6kw/Roll film/Automatic Pouch Packaging Machine(DXD-240F)

1.Description of the ≤200ml (single bag); ≤100 × 2 = 200 ml (double bag)/6kw/Roll film/Automatic Pouch Packaging Machine(DXD-240F)

DXD-180G full-automatic horizontal bagging machine consists of motor film releasing, bag forming, bag bottom sealing, vertical sealing, servo bag pulling, shearing, bag opening detection, bag opening filling, bag transfer, bag mouth dust removal, bag top sealing and other mechanisms. The coordinated action of each mechanism is completed by the cam on the main shaft driven by the motor, and the position signal is fed back by the encoder on the main shaft under the programmable control of PLC, The functions of film roll → bag forming → bag making → bag opening detection → filling → bag wiping and dust removal → sealing → finished product transportation are realized. Finally, it is packed or boxed manually.

The machine has reasonable design and novel appearance. After replacing the filler, it can realize the automatic filling of powder, particle, suspending agent, emulsion, water agent and other materials on the machine. The whole machine is made of SUS304 stainless steel, which has good anti-corrosion effect on highly corrosive materials. Toughened glass cover to prevent dust leakage, more beautiful and more environmentally friendly.

2.Parameters

| Productive Power |

40-60 bags / min (single bag)( 40-60) x2 = 80-120 bags / min (double bag) |

| Applicable Bag Size |

Single bag: 80 × 120mm (minimum); 180× 220mm (max.)

Duplex bag: (80 + 80) × 120mm (min.) (120+120) × 180mm (max.) |

| Applicable Bag Type |

Single Bag/Double Bag |

| Packaging Capacity |

Routine: ≤ 200ml (single bag); ≤100 × 2 = 200 ml (double bag) |

| Roll Film Size |

Inner Diameter: Φ 70-80mm Outer Diameter: ≤ Φ 500mm |

| Filling Precision |

±1% |

| Air Pressure |

840L/min |

| Power |

AC380V 50Hz/6KW |

| Equipment Size |

4500×1040×2400mm(L×W×H) |

3.Features

(a)More efficient: the full-automatic horizontal bagging machine adopts the form of double scissors to improve the production capacity. For single bag filling, the production capacity is doubled on the original basis (this function is optional).

(b)The static elimination rod eliminates static electricity at the roll film to ensure more stable bag opening (this function is optional).

(c)Film changing and bag receiving device: when a roll of film is used up, there is no need to pull out the remaining roll of film on the equipment. Just bond it with the new roll of film on this device to continue to start up and reduce the loss of packaging materials( This function is optional)

(d)Diamond Tear: an independent tear mechanism is adopted, and the air cylinder drives the cutter to move back and forth to achieve the tear effect. It is easy to tear and beautiful. Its use effect is far beyond the hot block tear, and a fragment collection device is set on the tear device( This function is optional).

(e)In order to prevent sticking, bag sticking, material sticking and other phenomena of hot block parts on the equipment after long-term use, special spraying shall be adopted on the surfaces of bottom seal, vertical seal, middle seal, top seal and other parts to avoid the above situations.

(f)Upgrade the servo bag pulling system to make the bag pulling precision more stable and accurate; Specification replacement, one key input, less packaging material loss.

(g)The virtual cutting hob device adopts the hob processed by special steel and the Italian kangmaosheng rodless cylinder to drive the rolling mechanism to move back and forth to achieve the virtual cutting effect. It is easy to tear and beautiful, and its use effect is far beyond hot virtual cutting (for duplex bags only)

(h)Weighing feedback system: measurement adjustment tentacles are available to reduce material waste (this function is optional).

(i)The versatility of the filling device: the equipment has reserved the connectors for powder, water, viscosity, granule and other filling devices, and the software is also reserved. Users can only install the connectors when changing the filling device, and can be used in the touch screen.

(j)IAutomatic greasing machine: pulsarlube-m automatic greasing machine imported from the United States is adopted to avoid the trouble of untimely manual maintenance cycle and prolong the service life of the mechanism( This function is optional)

(k)Threshold alarm: the safety door switch is added to the equipment to open and stop the door during production( This function is optional)

(l)Multiple safety protection (Shenshi color code detection, Japan SMC vacuum generator, air source processor with air pressure detection and power phase sequence protector) to ensure the stability and reliability of equipment operation to the greatest extent.

(m)Temperature control integrated module: real-time monitoring of temperature changes, the operation is clear at a glance. So as to effectively control the heat sealing mechanism, ensure the sealing reliability and make the packaged products easy to use and good-looking.

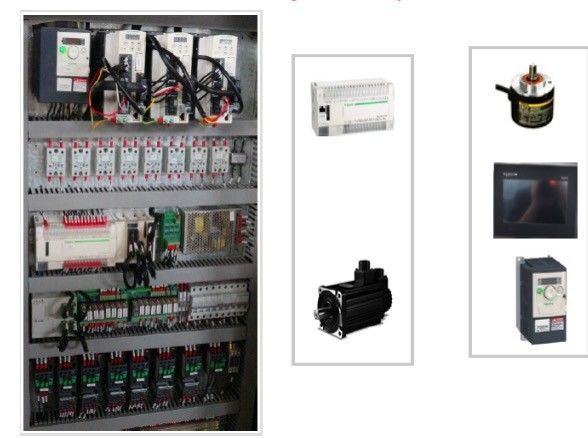

(n)Schneider Electric System (PLC programmable controller, man-machine interface, servo system, frequency converter, switching power supply, etc.) is mainly configured for the whole machine. Safer, more reliable, more efficient and environmentally friendly (bring you more economic energy loss).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!