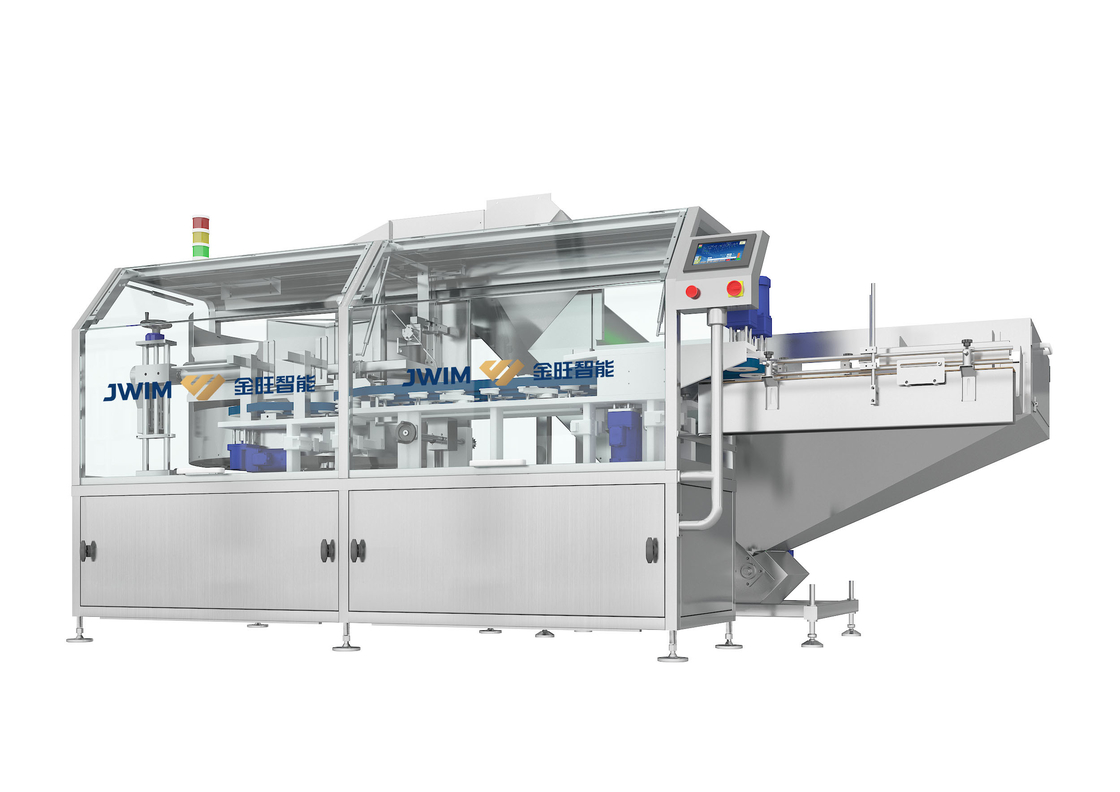

12000 BPH 50-1000ML Automatic Plastic Rotary Bottle Sorting Unscrambler Machine

1. Product Introduction of LP-200E Bottle Unscrambler

The machine LP-200E is a fully automatic unscrambler for bottles from 50ml to 1000ml. The Automatic Bottle Unscrambler with high speed of 10000 bottles per hour maximum depending on Bottles size. The Unscrambler structure transfer bottles directly from the Unscrambler to the machine belt system in inverted position with continues movement and then another set of belt gripping system invert the bottle into vertical position to move further for filling operation. Machine is supplied with elevator conveyor belt system for continuous supply of bottles to unscrambler.

2. Parameters of LP-200E Automatic Bottle Unscrambler Machine

| Unscrambling Speed |

50ml:200bottles/min;250ml:150bottles/min;

1000ml:110bottles/min

|

| Bottle Size |

Diameterφ40-95mm

Height 80-240mm

|

| Power Source |

~220V 50Hz/2.5KW

|

| External Dimension(without bottle elevator) |

2730*1450*1500mm(L*W*H)

|

| External Dimension |

3540*1800*1800mm(L*W*H)

|

| Weight |

About 900kg

|

3. Features of LP-200E Bottle Sorting Unscrambler Machine

① Bottle loading (bottle enters the bottle unscrambler turntable through the bottle loading machine)

② Bottle delivery (the round turntable sends the bottles to the unscramble station, and the belt in the turntable can be used for different bottle diameters by increasing or decreasing the belt in the turntable)

③ Kick the bottle (reject the overlapping bottles to facilitate bottle sorting)

④ Hook bottle (use the bottle hook device to stand the bottle hook upright with the bottle mouth facing forward)

⑤ Stand up the bottle (use the bottle stand up mechanism to erect the bottle with the bottom of the bottle facing forward)

⑥ Bottle Feeding out(the upright bottle is transported to the filling station through the conveyor belt)

⑦ Rejection of inverted bottles (detection of inverted bottles through photoelectric, and automatic rejection of inverted bottles into the upper bottle hopper by the mechanical inverting device)

4. Advantages of LP-200E Automatic Bottle Sorting Machine

① Small size and simple operation. The machine has a compact structure and a small footprint. The whole machine has only three operation buttons, easy to operate

② Easy to switch specifications. Specifications can be switched by simply changing the number of belts in the turntable and adjusting the width of the bottle-arranging belts.

③ Automatic bottle feeding. The turntable is equipped with detection photoelectricity, which realizes automatic bottle feeding when the bottle is insufficient, stops feeding when the bottle is sufficient, and automatically alarms when there is no bottle in the bottle feeding machine, without manual intervention.

④ Inverted bottle rejection device. When the sorted bottle is inverted, the rejection device automatically kicks the inverted bottle back into the collection bucket.

5. Why Choose Us?

Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd (JWIM) was established in May 2005. JWIM is a professional manufacturer engaged in agricultural and animal husbandry intelligent industry. We are a high-tech enterprise integrated with R&D, manufacturing, marketing, and service.

Our company focuses on the agriculture and animal husbandry industry, and so far it has obtained more than 100 patent certificates, among which are 8 invention patents and 8 utility model patents of JWIM intellectual formulation workshop. Our products have been exported to more than 50 countries all over the world. We have provided professional services to more than 3,000 agricultural and animal husbandry customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!