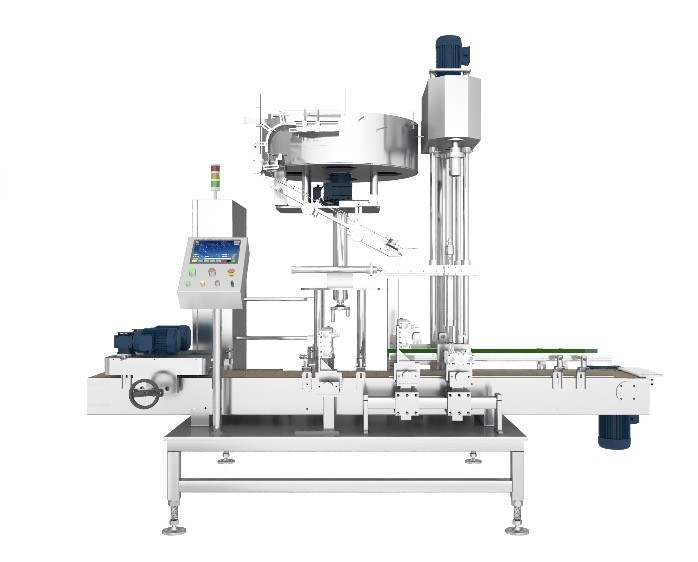

5-30L Drum Single-head Automatic Capping Machine

FX-1D single head capping machine is composed of cap sorting&conveying mechanism, cap grabbing&capping mechanism, conveying mechanism and control system.The whole machine has simple structure and convenient adjustment. It is suitable for automatic capping of 5-30l barrels.

Advanced Features

1. The machine comes with a SUS304 stainless steel environmental protection cover, on the top of the equipment with an exhaust port, the production process exhaust can be discharged. The machine meets the environmental protection requirements of the agrochemical industry, and can truly achieve tasteless production.

2. Using the Schneider system and allocations, much more integrated and stable.

3. High precision: individual motor driven the capping process, torque adjustable, do not hurt the cap, and ensure the constant torque, 100% qualification rate.

4. Automatic positioning the cap, and no liquid shake out.

Technical parameter

| 1 |

Capacity |

≤500 barrels/hour |

| 2 |

Distance from liquid level to bottle mouth |

≥200mm |

| 3 |

Qualified rate |

≥99% |

| 4 |

Applicable bottle size |

Min:140×200×320mm Max:260×290×410mm |

| 5 |

Applicable cap size |

Φ35-75mm H20-40mm |

| 6 |

Air pressure |

0.6MPa |

| 7 |

Power supply |

~220V 50Hz |

| 8 |

Power |

2.0KW |

| 9 |

Machine weight |

800Kg |

| 10 |

Machine size |

2195×1490×1950mm(L×W×H) |

Technological process

1. Cap sorting (cap sorting by rotary table, front cap goes into cap falling groove, reversed cap will be kicked back to cap sorter)

2. Bottle feeding (before entering the capping part, use the belt to clamp the bottle and feed the bottle separately)

3. Grab the cap (scrape the cap under the gripper with a mold, grab the cap with a three claw gripper, and prepare to screw the cap)

4. Screw cap (Use mold positioning to screw the cap)

5. Bottle out (after capping, the bottle goes out of the equipment)

Equipment advantages

1. The electric control system of the whole machine adopts Schneider configuration and integrated electric control system, which is more stable, reliable, safe, green and low energy consumption.

2. High-precision: The cap is screwed by an independent motor, and the torque is adjustable without damaging the cap, so as to ensure that the torque of the cover is constant, and the qualified rate is 100%.

3. The mold automatically positions the cap,screwing process is stable and without bottle shaking.

4. The enlarged cap sorter has simple adjustment and is suitable for all kinds of general cap types.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!