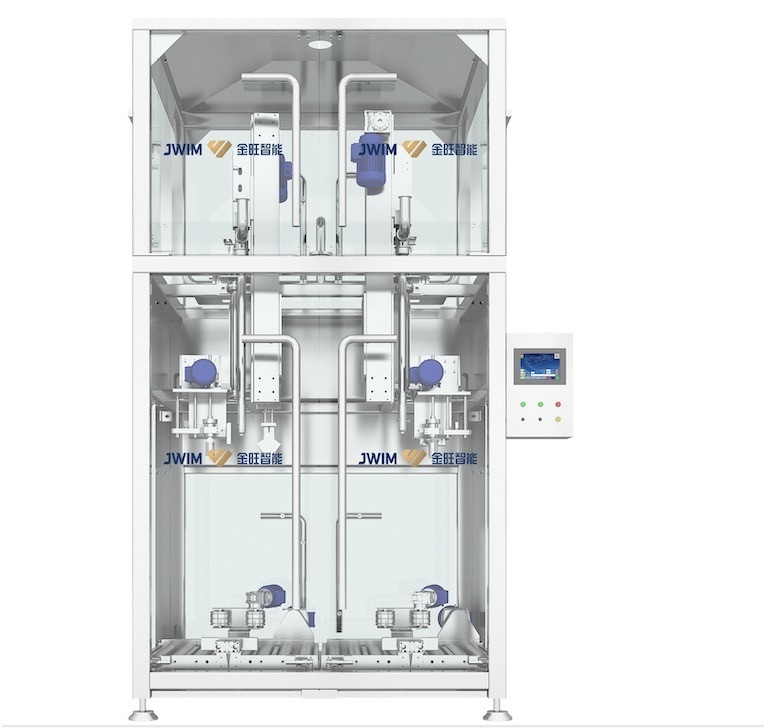

Accurate Semi Automatic Disinfectant Filling Machine High Precision

1. Introduction

CC300-2-2 Fixed Quantity Weight Filling Machine adopts the weighing to monitor the current filling quantity in real time and feedback to the controller, which outputs fast and slow filling control signals according to the set data to achieve fast and accurate filling of big containers. It makes up for the traditional filling machine cannot accurately measure the filling of viscous liquid. It can meet the needs of a variety of liquid automatic filling both with and without foam. Meanwhile, it can realize the automatic cap unloading and capping.

2.Main Technical Parameters

| 1 |

Capacity |

≤60 Drums/hour (Depends on material) |

| 2 |

Drum Diameter |

500-700mm, height: 800-1000mm |

| 3 |

Filling range,filling nozzles |

10-300kg

2 nozzles

|

| 4 |

Accuracy |

±0.2% (Depends on material viscosity and the consistency & stability of material feeding) |

| 5 |

Power Source: |

~220V, 50HZ |

| 6 |

Power:

|

10 KW |

| 7 |

Air Pressure:

|

0.5-0.7MPA |

| 8 |

External Dimension: |

1680×1490×2350 (L×W×H) mm

|

| 9 |

Weight: |

2000 KG |

3. Features

3.1 Compacted structure and simple operation.

3.2. High Precision: Adopts America METTLER TOLEDO weighing sensor and control meter, ensures that the filling precision of measurement.

3.3 The process is like this: Two empty drums will enter the filling machine, auto positioning and aim at the mouth, filling head going down, fast filling ,slow filling, valve close, filling head going up, filled drum going out, empty drums enter again.

3.4 Liquid holder can be added on the filling head, it will hold the liquid drops after filling to avoid the liquids pollute the drums

3.5 The filling machine is with SUS304 frame which can be used in the agrochemical industry, Stainless steel cover and organic glass cover seal the machine, the air ventilation hole on top of the filling machine can connect with the ventilation system to discharge the air during production

Features:

1. Process: Manual Drum Placing——Auto Drum Feeding——Auto Cap Unloading——Auto Weight Filling——Auto Capping——Auto Drum Discharge (Note: After cap unloading, The cap is ready in the capping station through the cap conveyor)

2. Drum feeding, drum dividing and drum retaining mechanism, adopts cylinder on both sides to push the connecting rod mechanism to achieve accurate and firm drum dividing and bucket retaining mechanism for empty drum. When filling is complete, when the full drum is transported to the next station, the bucket retaining cylinder is withdraws and the empty bucket enters the filling machine.

3. Two empty drums come into the integrated machine as a unit. The drums are placed by the roller, auto cap unloading, filling nozzle automatically aims to the drum opening, filling nozzle going down, fast & slow filling. The nozzle going up after filling, auto capping, the filled drum goes out and enters the empty drum.

4. Auto cap unloading and capping system: It can do auto cap unloading and capping to the drums. (water-proof cap should be handle manually)

5. Fast and slow filling valve is adopted to ensure the accuracy of filling without affecting the overall filling speed. With filling nozzle diving mechanism, it can both fill on or under liquid surface, suitable for filling products with no foam or slight foam.

6. High Precision: Weighing filling (US Mettler Toledo Weighing Sensor) to make sure the high filling precision.

7. The filling head is equipped with a rotating liquid cup. After filling, the liquid cup will collect the residual material on the filling head to prevent the product from leaking and contaminating the container.

8. The machine uses France Schneider Control system to control the operating stability. Meanwhile, the control system is with low energy consumption.

9. An air outlet is reserved at the top of the machine, which can connect with the customer's air diversion system to ensure the workshop production environment

10. Multiple Working Station: According to years of market experience, the machine can separate the cap unloading, capping and filling. Each action works separately, to achieve high efficiency, precision and no deviation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!