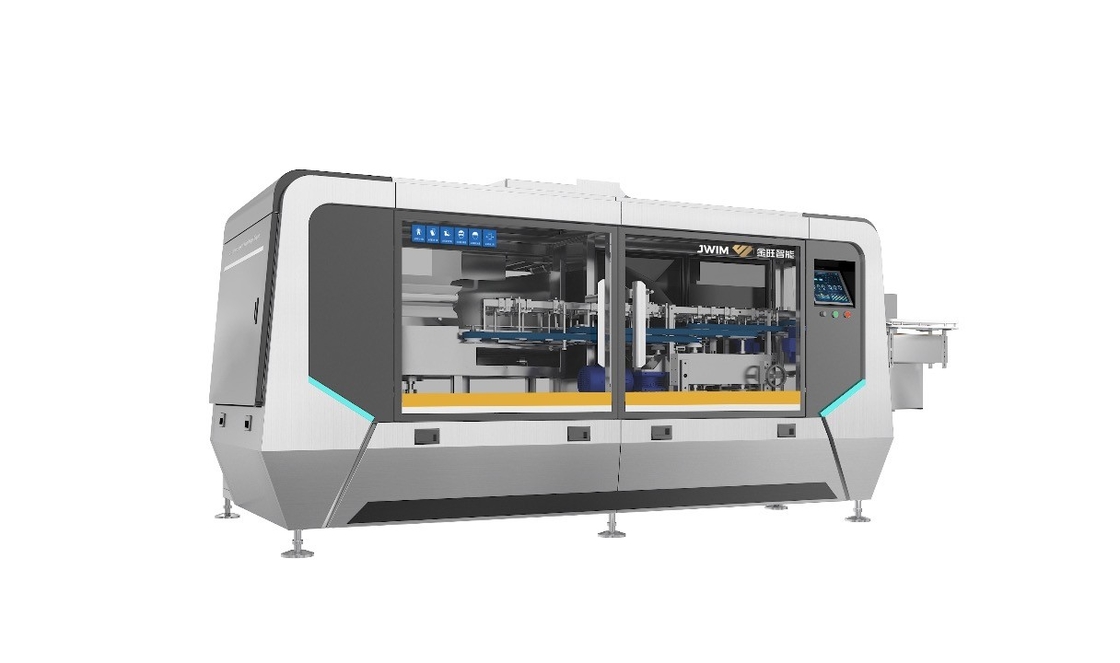

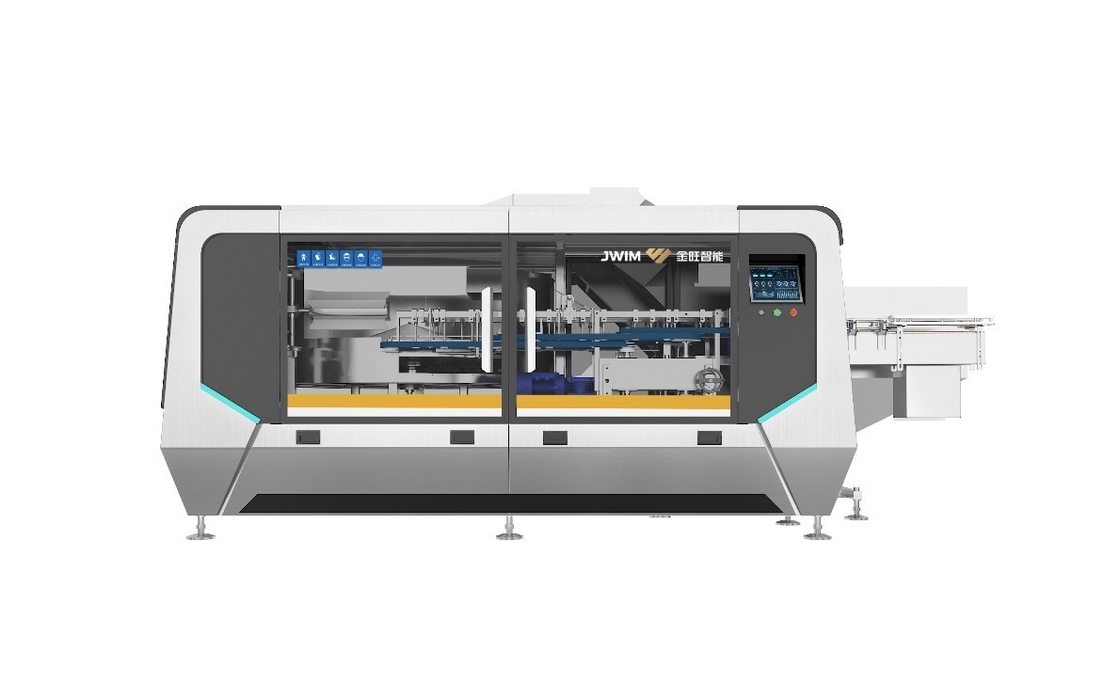

LP-300H Automatic Bottle Unscrambler Machine 50-1000ml Round Bottle Compact Easy Automatic Bottle Unscrambler

Introduction

The LP-300H automatic bottle unscrambler consists of a bottle loading machine, a bottle unscrambler turntable, a bottle reject component, a bottle unscrambler component, an inverted bottle reject component and an electrical box. A large number of disordered bottles are put into the bottle unscrambler turntable by the bottle loading machine, and are transferred to the unscrambler part through the conveyor belt, so that the bottles can be conveyed upright to the user's conveyor belt.

The turntable of this model is enlarged, the unscramble mechanism is lengthened, and the bottle opening is wider, and the production capacity is faster.

2. Technical Parameters

| 1 |

Unscrambling Speed |

100ml:≥18000bottles per hour

*speed will be affected by the bottle size, bottle material

|

| 2 |

Bottle Diameter |

Round bottles:Φ40-95mm Bottle Height 80-240mm |

| 3 |

Air Source |

0.5-0.7MPa |

| 4 |

Power Source |

~220V 50Hz/3KW |

| 5 |

External Dimension |

3450×2245×2030mm(L×W×H) |

| 6 |

Weight |

~1000Kg |

3. Electric Allocations of 50-1000ml Bottle Unscrambler

| No. |

Name |

Brand |

| 1 |

PLC |

Schneider |

| 2 |

Touch Screen |

Schneider |

| 3 |

Frequency converter |

Schneider |

| 4 |

Count Photoelectric |

SICK |

| 5 |

Switching power supply |

Schneider |

| 6 |

Solenoid Valve |

FTEC |

| 7 |

Circuit Breaker |

Schneider |

| 8 |

Intermediate relay |

Schneider |

| 9 |

Alarming Light |

Schneider |

| 10 |

Exhaust Fan |

SUNON |

| 11 |

Turbo Reducer |

UCAN |

| 12 |

Motor |

UCAN |

Advanced Features

1.High appearance: The whole machine adopts high-speed rail appearance, beautiful and generous, strong sense of science and technology, and high-grade.

2. The structure is compact, the operation is simple and with good compatiability., suits for 50-1000ml bottle.

3. The bottle mechanism of the whole mechanism is lengthened and the line speed is increased to ensure that the maximum speed can reach 18,000 bottles/hour (100ml as an example).

4.When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml bottle.

5.The bottle loading machine adopts a new mechanism, and the bottle opening is widened to ensure the efficiency of bottle loading. The turntable is enlarged to make full use of the enlarged bottle-dropping slot space to ensure the bottle-feeding speed.

1. Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

8. Automatic bottle loading function: only need to pour the bottle into the bottle filling machine, the turntable is equipped with detection photoelectric, realize the automatic filling of the bottle when the bottle is insufficient, and stop the bottle feeding when the bottle is enough. The bottle feeding machine automatically alarms without any manual labor intervention.

9. Equipped with inverted bottle removal device, when bottle fall down, the photoelectric sensor will detects the inverted bottles, it will kicks the bottle back to the bottle collection bucket, without human intervention.

Advanced Features

1.High appearance: The whole machine adopts high-speed rail appearance, beautiful and generous, strong sense of science and technology, and high-grade.

2. The structure is compact, the operation is simple and with good compatiability., suits for 50-1000ml bottle.

3. The bottle mechanism of the whole mechanism is lengthened and the line speed is increased to ensure that the maximum speed can reach 18,000 bottles/hour (100ml as an example).

4.When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml bottle.

5.The bottle loading machine adopts a new mechanism, and the bottle opening is widened to ensure the efficiency of bottle loading. The turntable is enlarged to make full use of the enlarged bottle-dropping slot space to ensure the bottle-feeding speed.

1. Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

8. Automatic bottle loading function: only need to pour the bottle into the bottle filling machine, the turntable is equipped with detection photoelectric, realize the automatic filling of the bottle when the bottle is insufficient, and stop the bottle feeding when the bottle is enough. The bottle feeding machine automatically alarms without any manual labor intervention.

9. Equipped with inverted bottle removal device, when bottle fall down, the photoelectric sensor will detects the inverted bottles, it will kicks the bottle back to the bottle collection bucket, without human intervention.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!