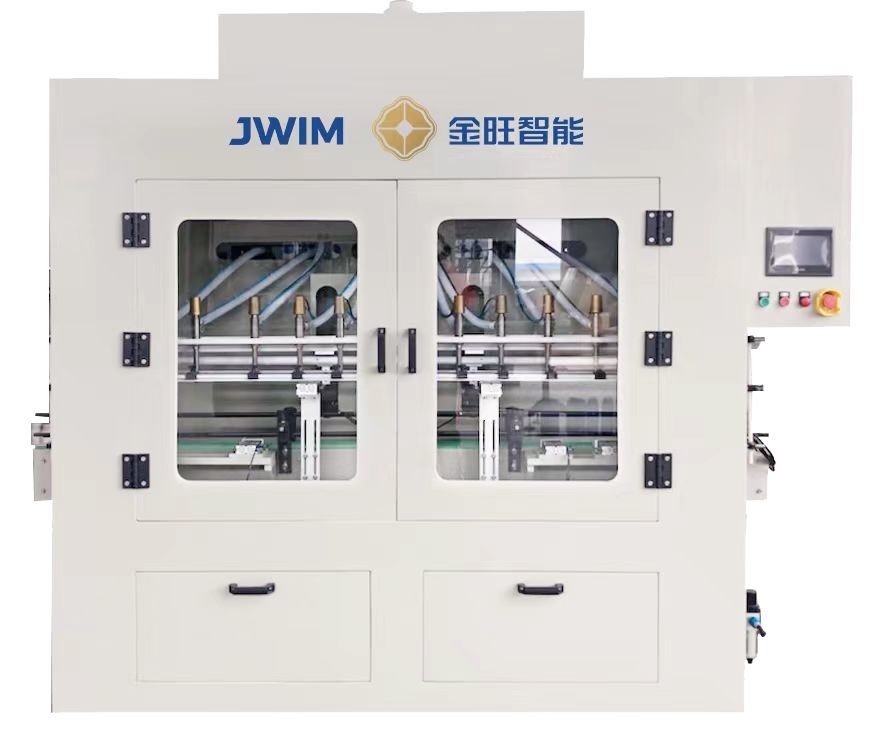

CCG1000-12FC Automatic Piston Filling Machine

1. Introduction

CCG1000-12FC Automatic Servo Piston Filling Machine is suitable for filling water-based products, especially for high viscosity materials, and has anti-corrosion function. Adopting PLC control, equipped with a touch screen human-machine interface system; Automatic bottle feeding, automatic filling, and automatic bottle output; Using servo motor drive, double ball screw drive, controlling the movement of the piston rod to ensure the stability of filling. This machine is equipped with a cylinder cleaning function, making it easy for customers to replace materials without the need for manual cleaning. It can be paired with capping machines and labeling machines to form a streamlined production line. It integrates light, machinery, electricity, and gas. It is a filling machine that is easy to operate. It has stable and reliable operation, high production efficiency, and strong adaptability.

2.Technical Parameters

| 1 |

Filling head |

12 |

| 2 |

Filling Volume |

50-1000ml

*Filling range differs from the product characteristic and product feeding.

|

| 3 |

Bottle Dimension |

Ф40-100mm |

| 4 |

Capacity |

Production speed with a filling volume of 250L and water as the medium≤4500BPH |

| 5 |

Filling Precision |

≤±0.5%

*Precision differs from product, drum and product characteristic.

|

| 6 |

Power Source |

~380V 50Hz/2.2KW |

| 7 |

Air Pressure |

0.55Mpa-0.65Mpa |

| 8 |

External Dimension |

2400×1350×2330mm(L×W×H) |

| 9 |

Weight |

About 1000kg |

3.Allocation

| No. |

Name |

Brand |

| 1 |

CPU |

Schneider |

| 2 |

HMI |

Schneider |

| 3 |

Inverter |

Schneider |

| 4 |

Servo System |

SICK |

| 5 |

Counting Sensor |

Schneider |

| 6 |

Cylinder |

AIRTAC |

| 7 |

Button |

Schneider |

| 8 |

Servo motor |

Schneider |

4.Features

4.1 The material cylinder is made of PVC strong acid and alkali resistant anti-corrosion material.

4.2 The discharge pipe adopts a PTFE , which has corrosion resistance. The feeding nozzle is made of titanium, which is corrosion-resistant and has precise filling without dripping.

4.3 Using servo motor drive and ball screw drive to ensure stable piston movement, high stroke accuracy, and precise filling from the surface.

4.4 The sealing components are made of anti-corrosion materials, which improve wear resistance and service life, and reduce maintenance costs.

5.Support and Services:

Pesticide Filling Machine Technical Support & Services

Our technical support and services for the Pesticide Filling Machine are designed to provide the most comprehensive assistance for our customers. Our team of experienced engineers and technicians are available to provide assistance with installation, maintenance, troubleshooting, and repair services.

We offer in-house training on the operation and maintenance of the machine to ensure that our customers can get the most out of their purchase. Additionally, we provide online support through our website, which includes FAQs, product manuals, and other helpful resources.

If you ever have any questions or concerns about the Pesticide Filling Machine, our team of experts are available to help. We believe that customer satisfaction is our top priority, and we strive to provide the best technical support and services possible.

6.Packing and Shipping:

Packaging and Shipping

The Pesticide Filling Machine will be securely packaged in a cardboard box to protect it during shipping. We will use a reliable carrier to ship the product to the customer's address.

7.FAQ:

Q1: What is the Brand Name of the Pesticide Filling Machine?

A1: The Brand Name of the Pesticide Filling Machine is JWIM.

Q2: What is the Model Number of the Pesticide Filling Machine?

A2: The Model Number of the Pesticide Filling Machine is CZ-6B.

Q3: Where is the Pesticide Filling Machine manufactured?

A3: The Pesticide Filling Machine is manufactured in China.

Q4: Does the Pesticide Filling Machine require special maintenance?

A4: The Pesticide Filling Machine requires regular maintenance to ensure proper operation.

Q5: What is the capacity of the Pesticide Filling Machine?

A5: The capacity of the Pesticide Filling Machine is determined by the size of the container to be filled.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!