1. Introduction

CC1000-2 Ton Drum Filling Machine adopts the weighing to monitor the current filling quantity in real time and feedback to the controller, which outputs fast and slow filling control signals according to the set data to achieve fast and accurate filling of big containers. It can meet the needs of a variety of liquid automatic filling both with and without foam.

2.Technical Parameters

| 1 |

Filling Range |

1000kg |

| 2 |

Division Value |

200g |

| 3 |

Filling Precision |

±0.1%

*Precision differs from product, drum and product characteristic.

|

| 4 |

Capacity |

1000L:5Drums/hour

*Capacity differs from product, drum and product characteristic.

|

| 5 |

Material temperature |

Normal temperature |

| 6 |

Weighing device |

1200×1200×90mm(L×W×H) |

| 7 |

Maximum pallet size |

1200×1200×150mm(L×W×H) |

| 8 |

Applicable ambient

temperature range

|

0-40℃ |

| 9 |

Relative humidity |

56-78%,non-condensing |

| 10 |

Power Source |

~380V 50Hz/0.6KW |

| 11 |

Air Pressure |

0.6-0.8MPa |

| 12 |

Material pressure |

≤0.2MPa |

| 13 |

Product Feeding Height |

1700mm |

| 14 |

Product Feeding Diameter |

DN50 |

| 15 |

Opening Diameter |

≥φ58mm |

| 16 |

External Dimension |

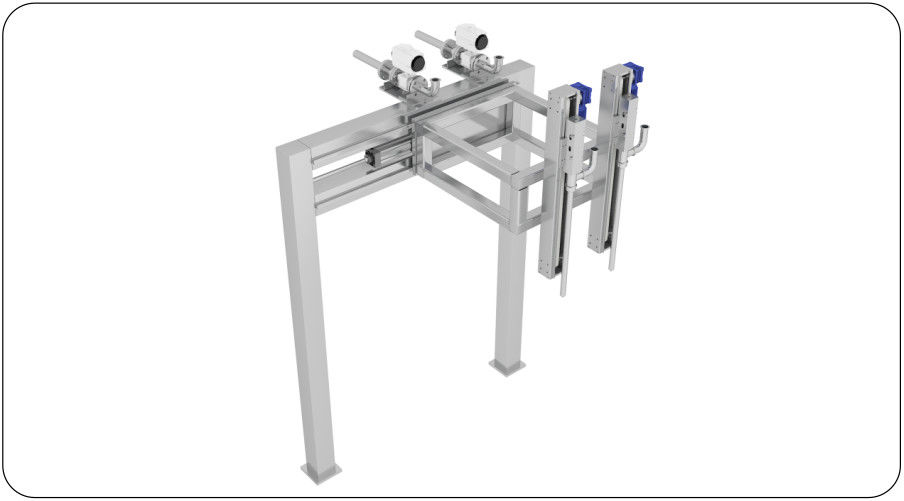

2340×685×4000mm(L×W×H) |

| 17 |

Weight |

1300kg |

| 18 |

The column of the filling machine needs to be fixed on the ground with expansion screws. |

3.Allocation

| No. |

Name |

Brand |

| 1 |

PLC |

Schneider |

| 2 |

HMI |

Schneider |

| 3 |

Inverter |

Schneider |

| 4 |

Servo System |

Schneider |

| 5 |

Counting Sensor |

SICK |

| 6 |

Proximity Switch |

Schneider |

| 7 |

Power Switch |

Schneider |

| 8 |

Pressure Gauge |

SMC |

| 9 |

Cylinder |

FTEC |

| 10 |

Solenoid Valve |

FTEC |

| 11 |

Button |

Schneider |

| 12 |

Alarm Light |

Schneider |

| 13 |

Circuit Breaker |

Schneider |

4.Features

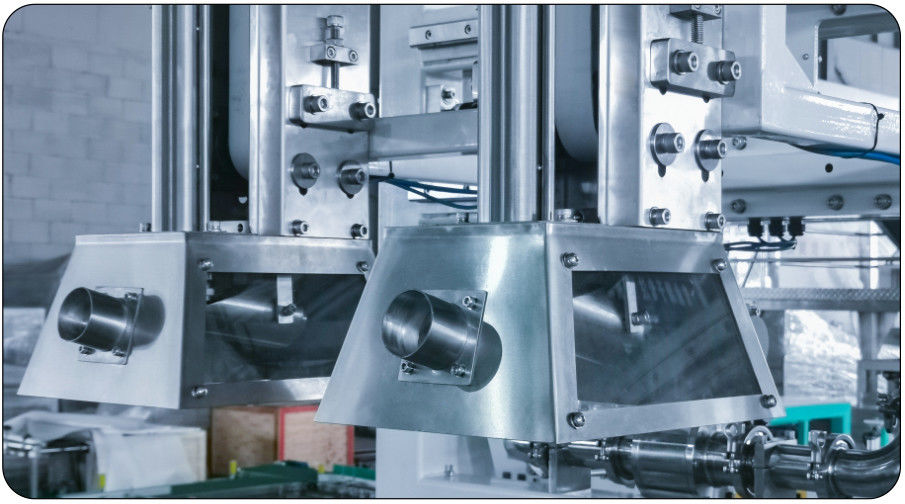

4.1 The double filling station of gantry frame can freely switch the production demand of A/B products. And the filling station is independently controlled, eliminating the adjustment time of personnel.

4.2 Fast and slow filling valve is adopted to ensure the accuracy of filling.

4.3 Submersible filling head to avoid material spatter.

4.4 Small footprint, compact structure, simple to use, only one person to operate, save labor.

4.5 High Precision: Weighing filling (US Mettler Toledo Weighing Sensor) to make sure the high filling precision.

4.6 The filling head is equipped with a rotating liquid cup. After filling, the liquid cup will collect the residual material on the filling head to prevent the product from leaking and contaminating the container.

4.7 Nitrogen can be filled by diving up with the filling head.

4.8 Automatic diagnosis, automatic fault alarm function, improve the reliability of the system.

4.9 Tare detection function, used to detect whether the container on the scale table is correct or there are materials in the container.

4.10 The machine adopts the latest Schneider electric Control system, stable control, and relatively low power consumption.

5.Support and Services:

Pesticide Filling Machine Technical Support & Services

Our technical support and services for the Pesticide Filling Machine are designed to provide the most comprehensive assistance for our customers. Our team of experienced engineers and technicians are available to provide assistance with installation, maintenance, troubleshooting, and repair services.

We offer in-house training on the operation and maintenance of the machine to ensure that our customers can get the most out of their purchase. Additionally, we provide online support through our website, which includes FAQs, product manuals, and other helpful resources.

If you ever have any questions or concerns about the Pesticide Filling Machine, our team of experts are available to help. We believe that customer satisfaction is our top priority, and we strive to provide the best technical support and services possible.

6.Packing and Shipping:

Packaging and Shipping

The Pesticide Filling Machine will be securely packaged in a cardboard box to protect it during shipping. We will use a reliable carrier to ship the product to the customer's address.

7.FAQ:

Q1: What is the Brand Name of the Pesticide Filling Machine?

A1: The Brand Name of the Pesticide Filling Machine is JWIM.

Q2: What is the Model Number of the Pesticide Filling Machine?

A2: The Model Number of the Pesticide Filling Machine is CC1000-2.

Q3: Where is the Pesticide Filling Machine manufactured?

A3: The Pesticide Filling Machine is manufactured in China.

Q4: Does the Pesticide Filling Machine require special maintenance?

A4: The Pesticide Filling Machine requires regular maintenance to ensure proper operation.

Q5: What is the capacity of the Pesticide Filling Machine?

A5: The capacity of the Pesticide Filling Machine is determined by the size of the container to be filled.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!