FX-1D Automatic Capping Machine

1.Introduction

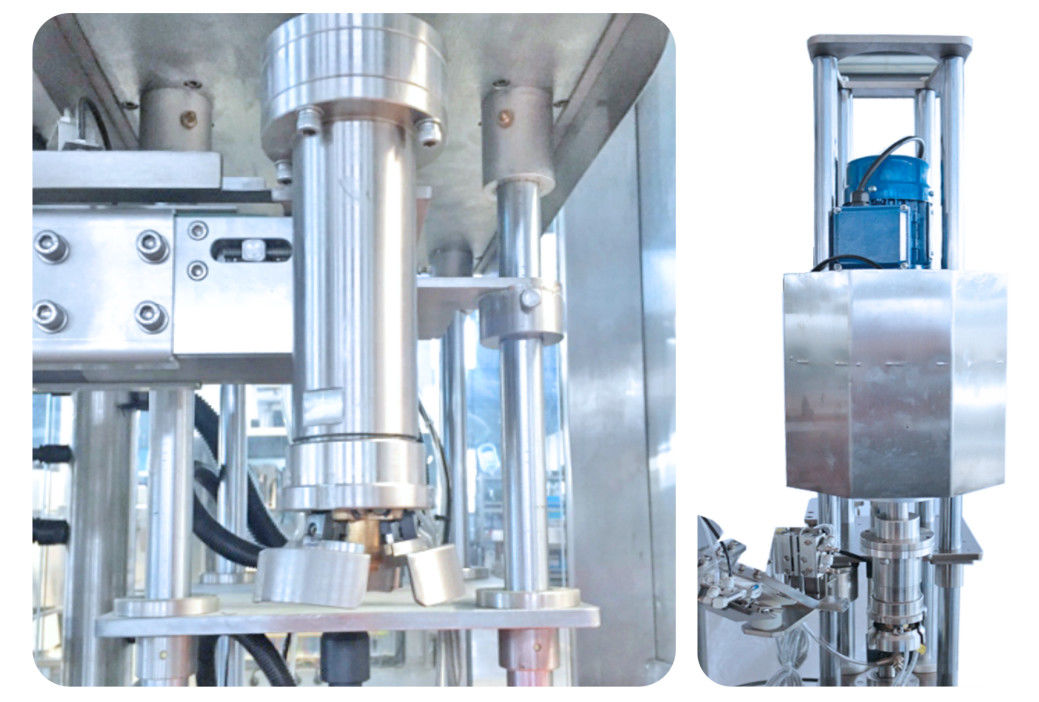

This machine consists of cap transfer mechanism, cap grabbing and capping mechanism, conveying mechanism and control system.

The whole machine is simple in structure, easy to adjust, and suitable for automatic capping of 5-30L drums.

2. Technical Parameters

| 1 |

Production capacity |

≤500 BPH

*Actual capacity varies according to product size, package material, material characteristics, etc.

|

| 2 |

Qualification rate |

99.9% |

| 3 |

Applicable barrel type |

Min:200×140×320mm Max:290×260×410mm |

| 4 |

Bottle cap specification |

Φ35-75mm H20-40mm

*It is recommended that the height of the lid does not exceed the diameter of the lid

|

| 5 |

Air pressure |

0.6~0.8MPa |

| 6 |

Electricity source |

~220V 50Hz |

| 7 |

Power |

1.2KW |

| 8 |

Weight |

700Kg |

| 9 |

Overall Dimension |

2555×1580×2235mm(L×W×H) |

3. Allocation

| S.N |

Name |

Brand |

| 1 |

PLC |

Schneider |

| 2 |

Touch Screen |

Schneider |

| 3 |

Frequency Converter |

Schneider |

| 4 |

Counting photoelectric |

SICK |

| 5 |

Switching power supply |

Schneider |

| 6 |

Pressure Switch |

SMC |

| 7 |

Cylinder |

FTEC |

| 8 |

Solenoid Valve |

FTEC |

| 9 |

Button |

Schneider |

| 10 |

Alarm Light |

Schneider |

| 11 |

Breaker |

Schneider |

4.Working Process

5.Features:

5.1 Widely used in agrochemicals, fine chemicals, daily chemicals, fertilizers, oils and other industries 5-30L square, flat barrels automatic capping.

5.2 The whole machine adopts French Schneider configuration, integrated electronic control system, more stable, reliable, safe, green, low energy consumption.

5.3 Extra-large capping device, easy to adjust the capping, suitable for all kinds of universal cap type.

5.4 High precision: independent motor capping, adjustable torque without hurting the cap, ensuring constant capping torque and high pass rate.

5.5 Mold automatic positioning capping, capping stable without shaking.

6.Support and Services:

Capping Machine Technical Support & Services

Our technical support and services for the Capping Machine are designed to provide the most comprehensive assistance for our customers. Our team of experienced engineers and technicians are available to provide assistance with installation, maintenance, troubleshooting, and repair services.

We offer in-house training on the operation and maintenance of the machine to ensure that our customers can get the most out of their purchase. Additionally, we provide online support through our website, which includes FAQs, product manuals, and other helpful resources.

If you ever have any questions or concerns about the Capping Machine, our team of experts are available to help. We believe that customer satisfaction is our top priority, and we strive to provide the best technical support and services possible.

7.Packing and Shipping:

Packaging and Shipping

The Capping Machine will be securely packaged in a cardboard box to protect it during shipping. We will use a reliable carrier to ship the product to the customer's address.

8.FAQ:

Q1: What is the Brand Name of the Capping Machine?

A1: The Brand Name of the Capping Machine is JWIM.

Q2: What is the Model Number of the Pesticide Capping Machine?

A2: The Model Number of the Capping Machine is FX-1D.

Q3: Where is the Capping Machine manufactured?

A3: The Capping Machine is manufactured in China.

Q4: Does the Capping Machine require special maintenance?

A4: The Capping Machine requires regular maintenance to ensure proper operation.

Q5: What is the capacity of the Capping Machine?

A5: The capacity of the Capping Machine is determined by the size of the container to be filled.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!