50ML-1000ML 6 Head Automatic Rotary Auto Screw Capping Machine

1. Product Introduction of FX-6AS Rotrary Automatic Screwing Capping Machine

The machine FX-6AS is an automatic capping machine suitable for round and square plastic or glass bottles from 50ml to 1000ml. Depending on the size of the cap, the production capacity is up to 6500 bottles per hour. The machine adopts a rotary structure, which does not damage the cap or the bottle body during the capping process, and the operation is more stable and efficient. The machine adopts PLC panel control, touch-type operation interface, easy to operate.

2. Parameter of FX-6AS Automatic Cap Screwing Machine

| Product Name |

FX-6AS Auto Feeding Screwing Caps Machine

|

| Qualified Rate |

≥99.9%

|

|

Applicable bottle type

|

Round bottle: Φ40-95mm H80-250mm

Square bottle: L45-110mm, W45-60mm, H80-230mm

|

| Cap Size |

Φ20-70mm, Cap Height 20-40mm

|

| Capping Head |

6

|

| Power Supply |

~380V, 50Hz/4.0KW

|

| Weight |

About 1600kg

|

| Dimension |

1995*1300*2246mm

|

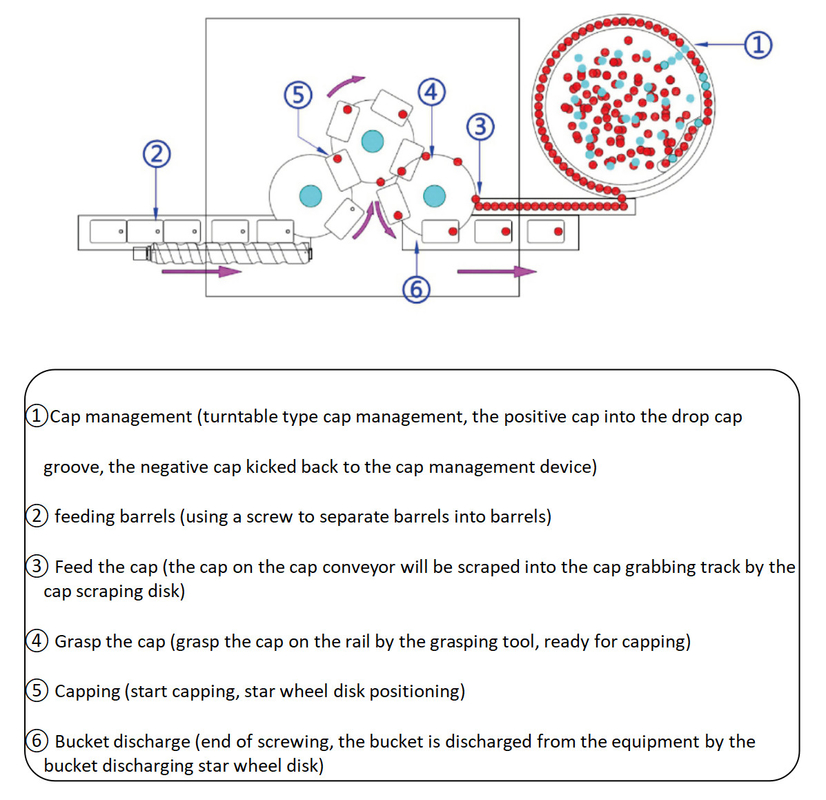

3. Working Process

① Cap sorting (rotary table type cap sorting, front cap goes into cap falling groove, reversed cap will be kicked back to cap sorter)

② Bottle feeding (Screw is used to separate bottles and feed bottles)

③ Cap feeding (the caps on the cap feeding frame are scraped into the grabbing track by the cap scraping disc)

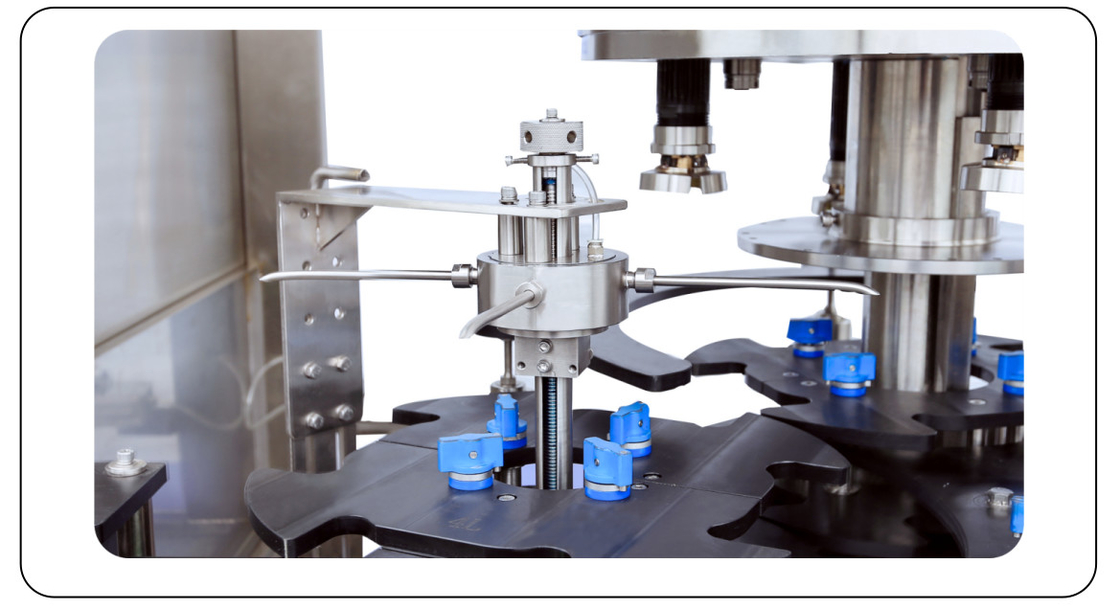

④ Grab the cap (grab the cap on the track and prepare to screw)

⑤ Screw the cap (start to screw the cap, belt stops the rotation of the bottle, and star wheel disc positions the bottle)

⑥ Bottle discharging (after capping, the bottle is discharged from the equipment by the bottle discharging star wheel)

4. Applicable Bottle Type

It is widely used in automatic capping of 50-1000ml bottles in pesticide, veterinary medicine, fine chemical industry, daily chemical industry, fertilizer, oil and other industries.

5. Advantages of FX-6AS 6 Head Automatic Rotary Capping Machine

① Quick installation mold. No tools are required for mold replacement. Moreover, the mold engraving identification is carried out according to different bottle types, the replacement of bottle type specifications is more convenient and fast, and the bottle type switching time is short.

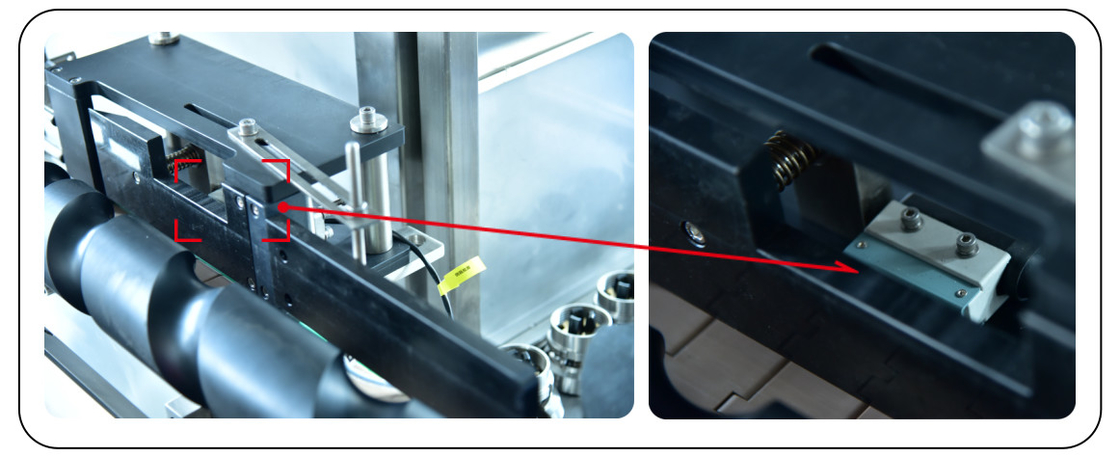

② Detection of inverted bottle and stuck bottle. When the bottle is inverted or the bottle is stuck, the equipment will automatically stop to avoid damage to the twist or star wheel.

③ Photoelectric detection cap sorting system. The adjustment is simple and stable, and the pass rate is as high as 100%. Enlarging the cap organizer, more cap storage and more stable cap management.

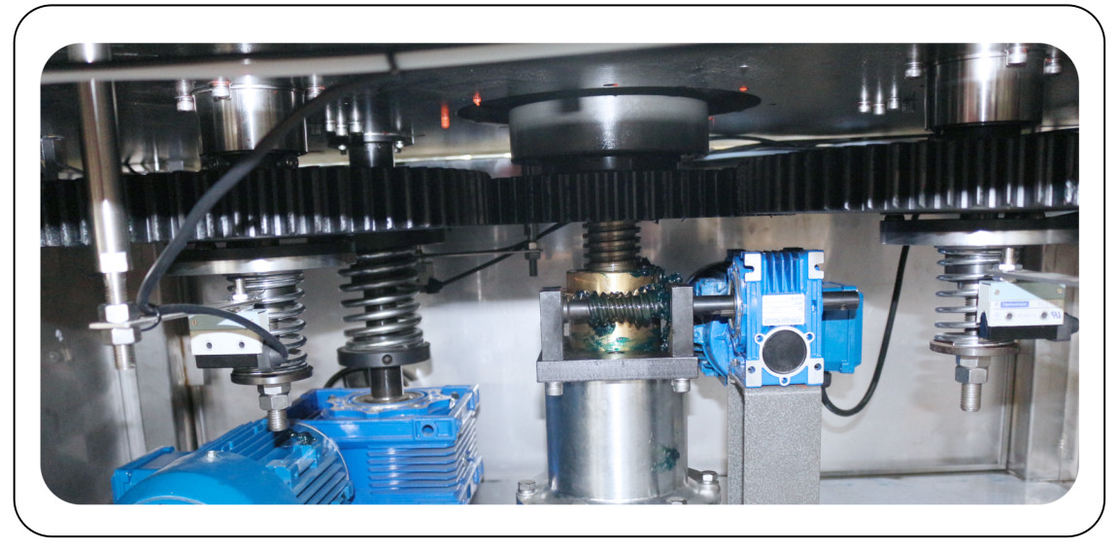

④ Humanized structure. Referring to the design structure of the world's top capping machine manufacturer AROL (Krones capping special supplier), it is equipped with automatic motor lifting (touch screen or jog button) and semi-automatic handle lifting adjustment mode, which is convenient and quick to adjust specifications. At present, similar capping machines on the market can only be adjusted manually, without automatic lifting function, or adopt V-belt drive, which cannot be manually lifted without power supply, and the adjustment is relatively cumbersome.

6. FAQ

Q: Are you a factory or trading company?

A: JWIM is a professional manufacturer engaged in agricultural and animal husbandry intelligent industry. We are a high-tech enterprise integrated with R&D, manufacturing, marketing, and service. At present, it has 600 employees and more than 300 technicians.

Q: If there’s something wrong with the equipment, how will you solve the problems quickly?

A: After getting customer’s problems, our engineer will analyze them through pictures or videos. If the problems are small, we will guide the customer to solve the problem by video call or guiding pictures; if there’s something wrong with parts, we will send the spare parts to the customer immediately; if there are some problems the customer can not solve and ask our engineer to site to check, our engineer will set out after getting the flight tickets from the customer.

Q: Payment Terms?

A: T/T 30%-50% deposit, and the balance should be paid before delivery.

Q:Machine Package?

A:Each Machine will be sprayed with antirust oil, wrapped by PO film for protection, and will be packed into the standard fumigation-free wooden cases.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!