Product Description:

The Chemical Liquid Filling Machine is an advanced liquid filling apparatus designed to meet the diverse needs of industries handling chemical products. Engineered with precision and reliability in mind, this automatic filling machine offers exceptional performance for filling a wide range of chemical liquids with varying viscosities and properties. Its versatile design ensures adaptability to different production environments, making it an indispensable tool for manufacturers seeking efficiency and accuracy in their filling processes.

One of the standout features of this chemical filling mechanism is its variable filling volume capability. This allows operators to easily adjust the filling quantity according to specific product requirements, ensuring minimal waste and precise dosage for each container. Whether filling small bottles or larger drums, the machine can be configured to deliver the exact volume needed, enhancing overall productivity and reducing material costs.

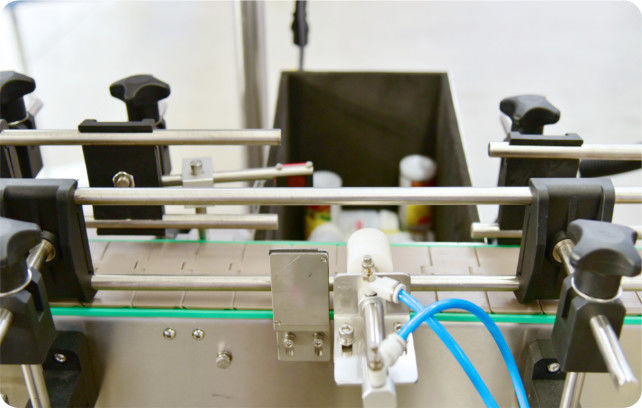

Equipped with multiple filling heads, the machine significantly boosts throughput by enabling simultaneous filling of several containers. This multi-head configuration not only accelerates the production line but also maintains consistency and uniformity across all filled units. The design supports a range of container sizes and shapes, providing flexibility to accommodate different packaging formats commonly used in the chemical industry.

The automatic filling machine operates under a sophisticated PLC (Programmable Logic Controller) control system, which ensures precise control over the entire filling process. The PLC system facilitates easy programming and monitoring, allowing operators to set parameters such as filling speed, volume, and sequence with high accuracy. This intelligent control system also enhances safety by integrating sensors and alarms that prevent overfilling, spillage, or other operational errors.

Customization is another key advantage of this liquid filling apparatus. Understanding that every production line has unique space and operational requirements, the machine’s dimensions can be tailored to fit specific facility layouts. This flexibility enables seamless integration into existing production setups without the need for extensive modifications, thereby saving time and reducing installation costs.

Beyond its technical capabilities, the chemical filling mechanism is constructed using high-quality materials that ensure durability and resistance to corrosion from harsh chemicals. The machine’s design prioritizes easy cleaning and maintenance, which is crucial for maintaining product purity and adhering to stringent safety standards in chemical manufacturing.

In summary, this Chemical Liquid Filling Machine represents a cutting-edge solution for chemical manufacturers seeking an efficient, reliable, and adaptable filling system. Its combination of variable filling volume, multiple filling heads, automatic operation, PLC control, and customizable dimensions makes it a superior choice for optimizing liquid filling processes. By integrating this automatic filling machine into their production lines, companies can achieve higher productivity, enhanced precision, and improved operational safety, ultimately driving better product quality and customer satisfaction.

Features:

-

Product Name: Chemical Liquid Filling Machine

-

Material: High-quality Stainless Steel for durability and corrosion resistance

-

Dimensions: Customized to fit specific production requirements

-

Filling Capacity: Variable to accommodate different volume needs

-

Power Supply: Operates on Electricity for efficient performance

-

Functionality as an Automatic Fluid Dispenser ensuring precise and consistent filling

-

Designed as a Chemical Liquid Dispenser suitable for various chemical fluids

-

Serves as a reliable Liquid Filling Apparatus for industrial and commercial applications

Technical Parameters:

|

Filling Range

|

Variable

|

|

Filling Method

|

Automatic

|

|

Filling Nozzle

|

Multiple

|

|

Control System

|

PLC

|

|

Filling Speed

|

High

|

|

Filling Accuracy

|

High

|

|

Power Supply

|

Electricity

|

|

Weight

|

Customized

|

|

Material

|

Stainless Steel

|

|

Filling Head

|

Multiple

|

Applications:

The JWIM Chemical Liquid Filling Machine, originating from China, is a highly efficient liquid filling apparatus designed to meet the diverse needs of various industries. Its automatic filling machine capabilities make it an ideal solution for businesses requiring precision and speed in their filling processes. With a high filling speed and variable filling capacity, this chemical filling mechanism is perfect for handling different types of chemical liquids, from low to high viscosity substances.

This machine is widely used in numerous application occasions, including pharmaceutical manufacturing, chemical production plants, cosmetic factories, and food and beverage industries. In pharmaceutical and chemical sectors, the JWIM liquid filling apparatus ensures accurate dosing of liquid chemicals, reducing waste and improving safety during the filling process. Its customizable dimensions and weight allow it to be adapted to specific production line requirements, making it highly versatile for various operational scenarios.

In automated production environments, the JWIM chemical filling mechanism integrates seamlessly with other equipment, enhancing overall workflow efficiency. Its automatic filling machine design supports high-speed operations without compromising accuracy, making it suitable for large-scale production runs. Additionally, the variable filling range accommodates different container sizes, from small vials to large drums, providing flexibility for manufacturers dealing with multiple product lines.

The machine is also ideal for use in laboratories and research facilities where precise liquid measurements are critical. Its reliable performance and ease of use enable operators to fill chemical liquids confidently and safely. Furthermore, the JWIM liquid filling apparatus is designed to comply with safety and environmental standards, ensuring it meets the rigorous demands of chemical handling and packaging.

Overall, the JWIM Chemical Liquid Filling Machine is an excellent choice for businesses seeking an advanced, customizable, and efficient chemical filling solution. Its combination of high-speed filling, variable capacity, and adaptability to different production scenarios makes it a valuable asset for any industry requiring precise and reliable liquid filling operations.

Customization:

JWIM Chemical Liquid Filling Machine is a high-performance liquid filling equipment designed to meet various industrial needs. Manufactured in China, this fluid dispensing machine features a reliable PLC control system that ensures precise and efficient operation. Equipped with multiple filling heads, it offers high filling speed to boost productivity. The machine's weight and configuration can be customized according to specific requirements, making it an ideal choice for diverse chemical filling mechanisms. Trust JWIM for advanced and adaptable chemical liquid filling solutions.

Packing and Shipping:

The Chemical Liquid Filling Machine is carefully packed to ensure safe delivery and optimal protection during transit. Each unit is securely wrapped with protective materials such as foam and bubble wrap to prevent any damage.

The machine is then placed inside a sturdy wooden crate or reinforced cardboard box, depending on the shipping requirements and destination. All packaging materials comply with international shipping standards to guarantee durability and safety.

For shipping, we offer multiple options including sea freight, air freight, and express courier services. The choice of shipping method will depend on the customer's preference, destination, and urgency of delivery.

Before shipment, each machine undergoes a thorough quality inspection and testing to ensure it meets the specified standards. Detailed user manuals and necessary accessories are included in the package to facilitate easy installation and operation.

We also provide tracking information for all shipments, allowing customers to monitor the status of their orders until delivery. Our team is committed to timely and secure delivery to ensure customer satisfaction.

FAQ:

Q1: What brand manufactures the Chemical Liquid Filling Machine?

A1: The Chemical Liquid Filling Machine is manufactured by JWIM.

Q2: Where is the JWIM Chemical Liquid Filling Machine made?

A2: The JWIM Chemical Liquid Filling Machine is made in China.

Q3: What types of liquids can the JWIM Chemical Liquid Filling Machine fill?

A3: This machine is designed to fill a variety of chemical liquids, including acids, solvents, and other industrial fluids.

Q4: Is the JWIM Chemical Liquid Filling Machine suitable for small or large scale production?

A4: The JWIM Chemical Liquid Filling Machine is suitable for both small and large scale production, offering adjustable filling volumes and speeds to meet different requirements.

Q5: What kind of maintenance is required for the JWIM Chemical Liquid Filling Machine?

A5: Regular cleaning and inspection of the filling nozzles and pumps are recommended to ensure optimal performance and longevity of the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!